How satisfied were

you with

Rudrra Sensors??

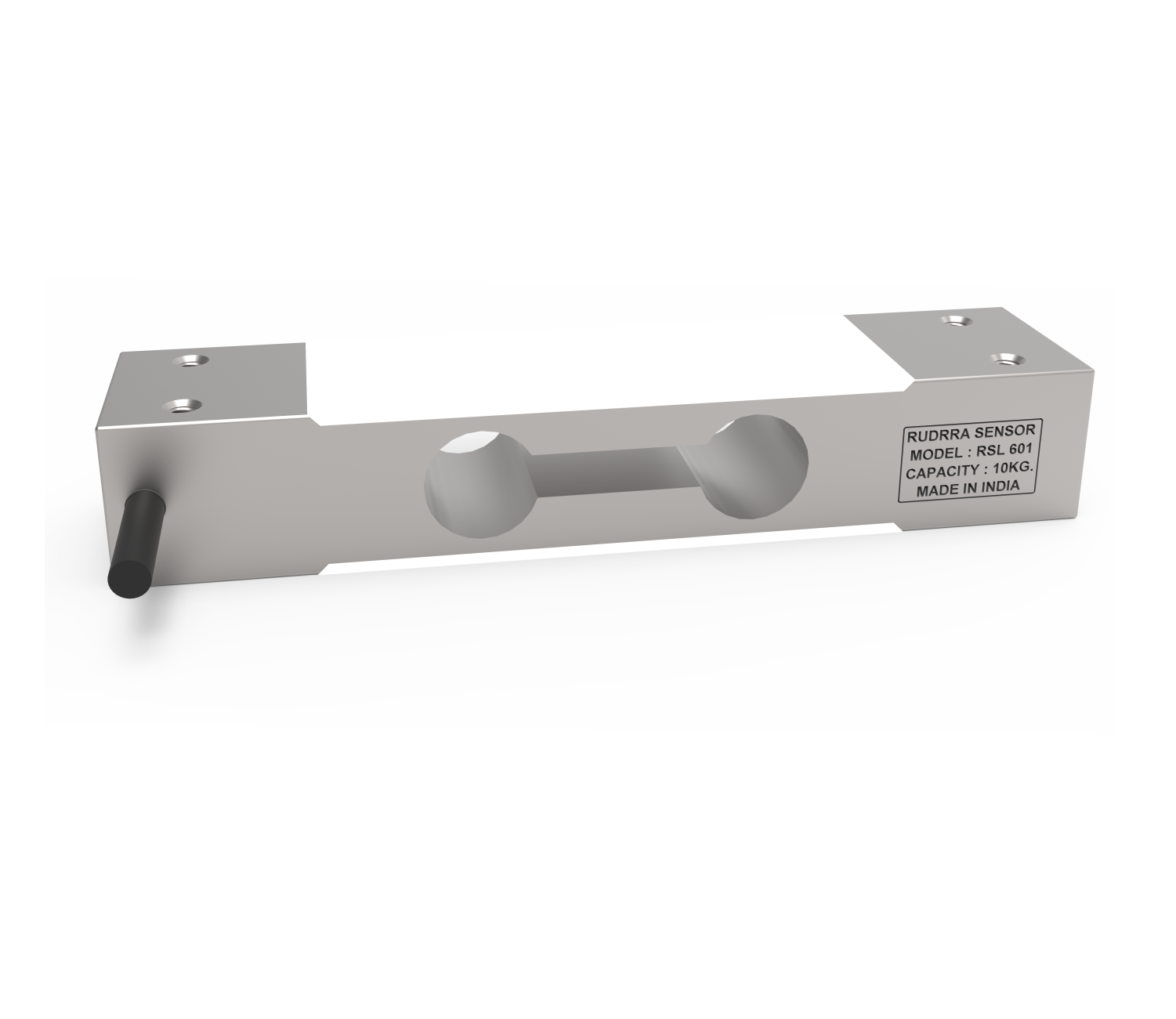

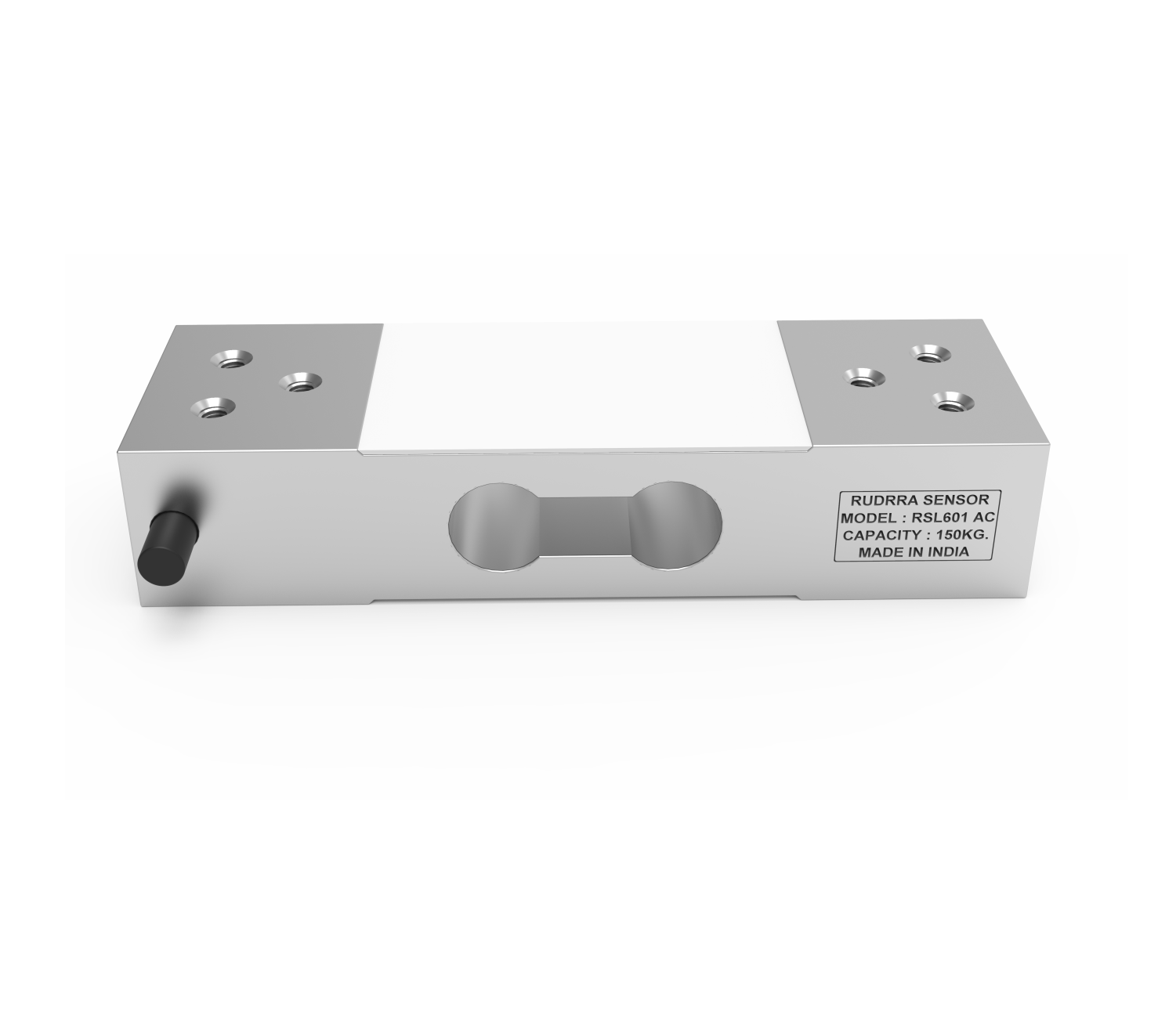

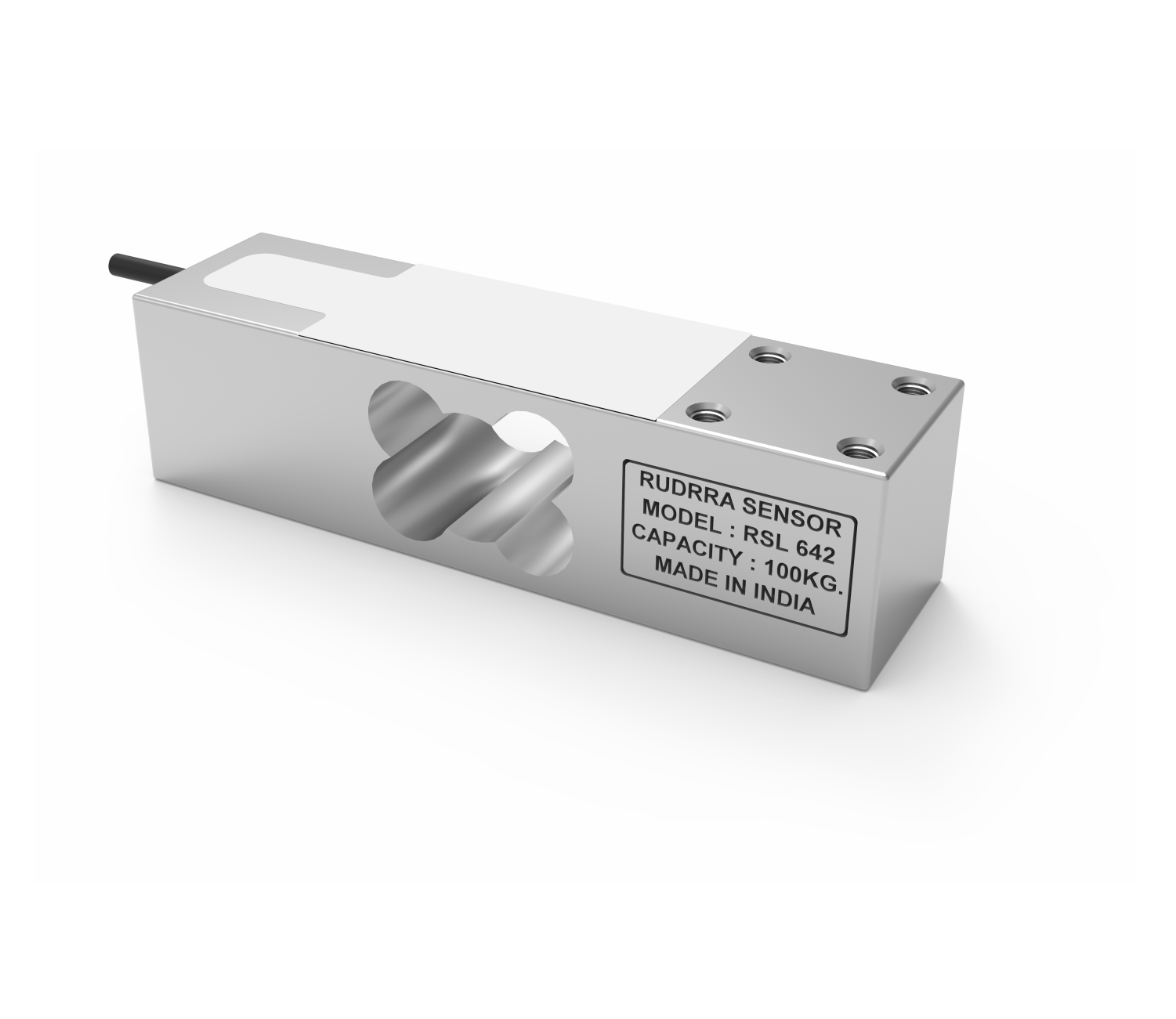

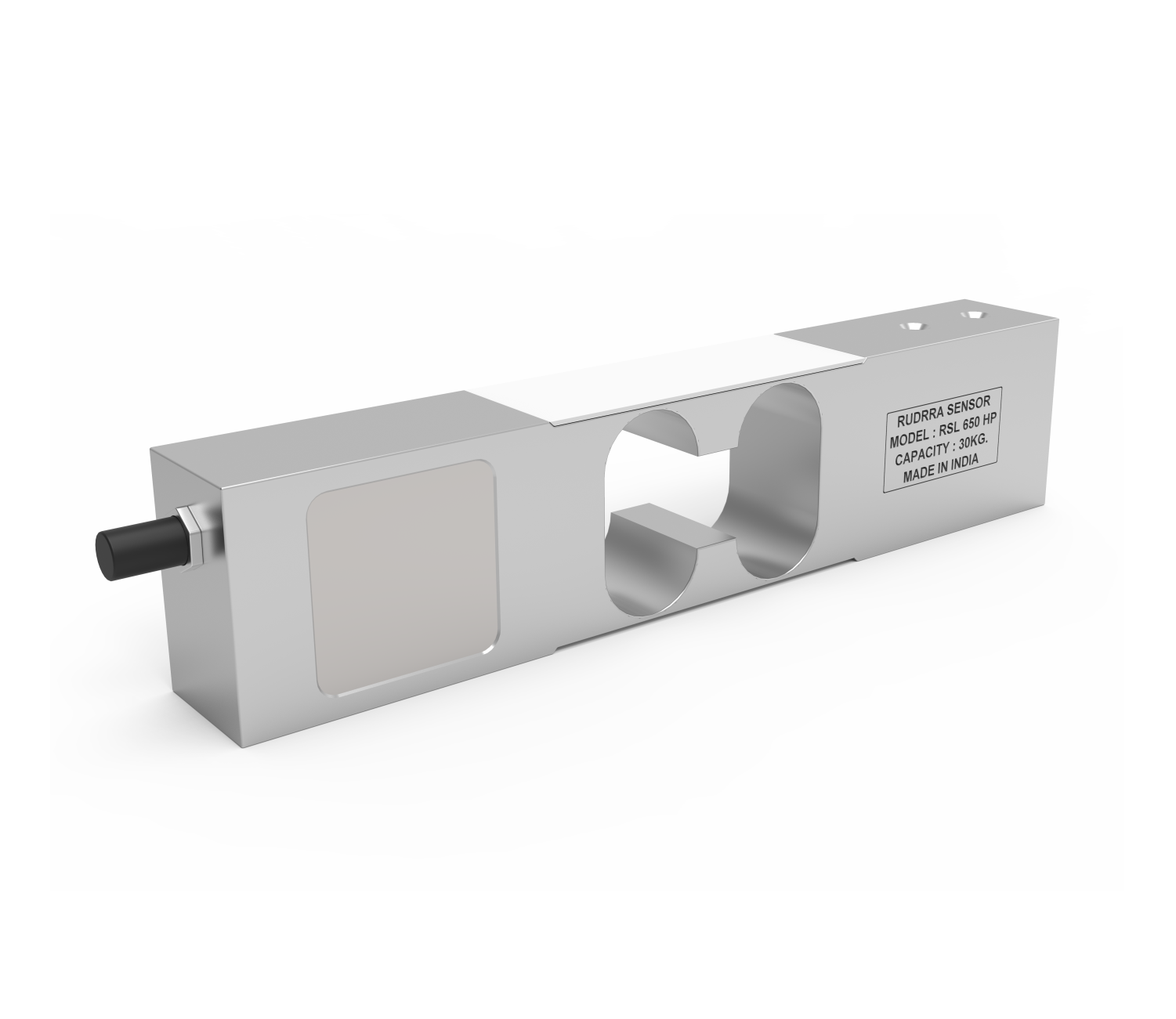

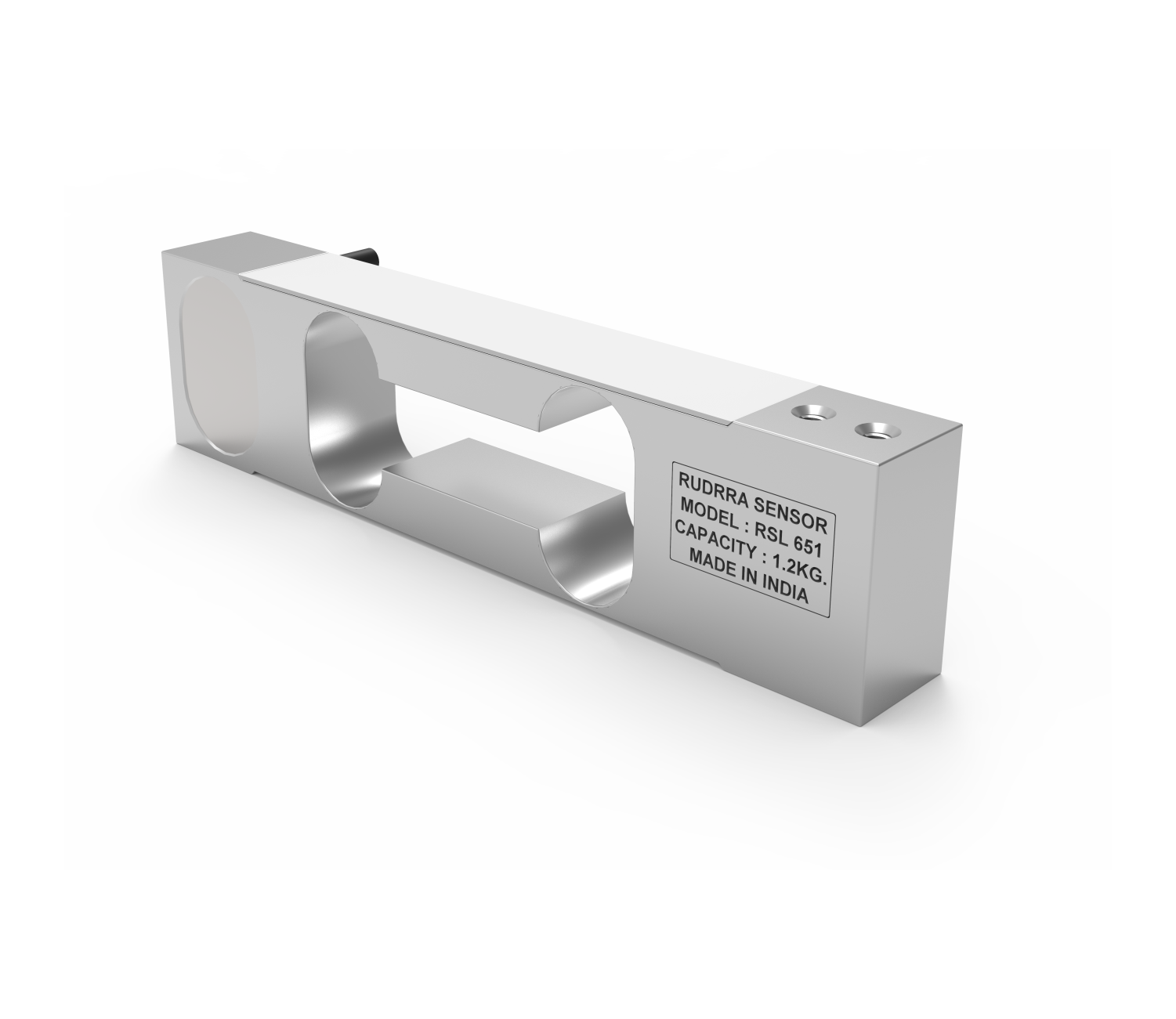

BEAM TYPE LOAD CELL

In the range of high-quality load cells, we also offer Beam Type Load Cell in different sizes and shapes. Our product is very strong and used for long-term usage. Our product is easy to install and use. Our products are elegantly designed in order to meet the needs of our most valuable clients. Owing to their low maintenance, easy operations, and leak-proof nature, these are extensively used by a number of industries in the market.

Rudrra shear beam load cell range is ideally suited to all industrial weighing scales and general measurement applications.

The beam type load cell family, sometimes known as a bending load cell, tends to be the most commonly used due to the variety of available options. Applications include filling machinery, industrial floor scales, tank and silo weighing, plus diverse applications in on-board vehicle weighing, medical equipment, and process control, where a load cell shear beam installation is required.

Get reliable, accurate measurements for hygienic processes using the Alfa Laval Weighing System with Beam Load Cells. These capacitive digital load cells tolerate very high overloads, sideloads, and torsion. Three standard accuracy ranges cover a weighing need from 0 to 4,000 kg and tolerate up to 300% overload. Perfect for use in the food, dairy, brewery, and pharmaceutical industries.

Reliable, accurate bending beam load cells for hygienic process weighing

- Maximize process uptime with high-precision, high-accuracy load cell measurement

- Cut costs and contamination risks thanks to a hygienic, hermetically sealed stainless-steel design

- Easy to install, operate, maintain, and clean due to compact footprint, load cell management, and straightforward design with no moving parts

- Versatile, customizable weighing solution with a broad range of Fieldbus interfaces, digital cables, and ATEX and IECEx versions

How it works

Our Beam Load Cells features patented digital capacitive technology that has a non-contact capacitive sensor mounted inside the load cell body.Each weighing system consists of several beam load cells, including load cell modules, an electronic output module (analog or digital), load cell weight sensors, load cell control modules, and cable. To ensure a robust and reliable connection between the tank and the load cells, Rudrra offers an additional range of tank legs that fit the load cells.

Factory pre-calibration does away with time-consuming onsite adjustments during commissioning. No costly, complicated mounting kits, stay rods, or overload protection devices. Just precise beam load cell weighing and management at its best.

When a load is applied, a portion of the load is transmitted to each load cell, which sends an electrical signal proportional to the load sensed to the control module. The control module converts the signals to an accurate weight reading.

Because there is no contact between load cell weight sensors and the load cell body, the load cells are largely unaffected by overload, side loads, torsion, shocks, and welding voltages. This makes straightforward mechanical load cell installation possible.

A proprietary application-specific integrated circuit (ASIC) in the beam load cell converts, compensates, and calibrates the output from the ceramic load cell weight sensors, enabling plug-and-play operation and accurate compression load cell measurement.

Buy Beam Load Cell

Our bending beam load cell is manufactured to the highest quality, ensuring that our sensors remain reliable and accurate. At the core of our shear beam load cell range is the use of stainless steel, combined with modern sealing compounds providing durability for most applications. For optimal durability, hermetically sealed versions are also available.

Our bending beam load cells are available with a list of standard or optional features. We have models that feature approvals such as OIML or NTEP, as well as versions approved for use in hazardous areas. Cable lengths, cable types, and connectors can all be adapted to match individual requirements.

In the range of high quality load cell we also offer Beam Type Load Cell in different size and shapes. Our product is very strong and used for long term usage. Our product is easy to install and use. Our products are elegantly designed in order to meet the needs of our most valuable clients. Owing to their low maintenance, easy operations and leak proof nature, these are extensively used by a number of industries in the market.