How satisfied were

you with

Rudrra Sensors??

Digital Weight Transmitter: Revolutionizing Industrial Weighing Systems

Digital Weight Transmitter is one of the essential components of industrial weighing systems. It offers high accuracy, better reliability & more efficiency. This advanced device has revolutionised the course of varied industries such as manufacturing plants, and logistic warehouses in terms of related processes & measurement. In this comprehensive guide, we will dive deep into the intricacies of digital weight transmitters, their components, applications, functionality & future trends.

Introduction to Digital Weight Transmitters

In today’s readily changing world, it is inevitable to have precise measurements for optimal processes & consistence quality of the products. Digital Weight Transmitter works as a pillar for the modern weighing system, ensuring real-time data acquisition & detailed analysis capabilities. Digital weight transmitters offer accuracy, stability & versatility compared to traditional analogue transmitters.

What are digital weight transmitters?

Digital Weight Transmitters are urbane electrical devices designed & developed to convert analog weight signals into digital data. These devices process the data, analysis & transmit it. These devices have elegant designs, are compact & widely used in healthcare, agriculture, logistics & manufacturing industries.

Key Feature :

International approved design

Light weight comport & cost effective

Din-rail mount digital amplifier

LED Display with Keypad for calibration

Password protected

Vibration filter

Application :

Signal conditioner

Convert to small mV signal into 0-10 VDC, 4-20mA, Rs485

Inventory Management

Batch Processing

Load Monitoring

Material Handling

Importance of Digital Weight Transmitter

Enhance Productivity

Profitability

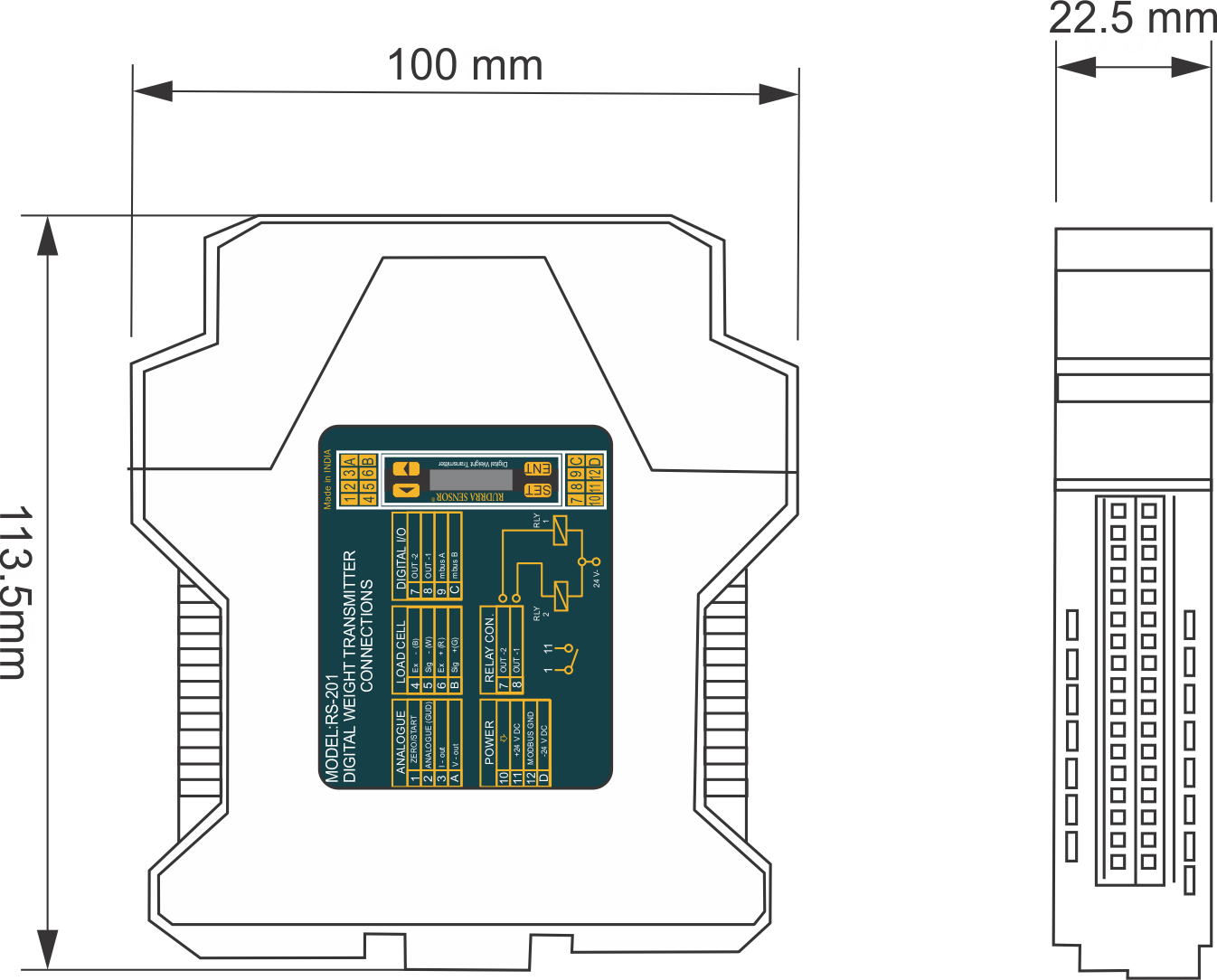

Dimensions :

Parameters :

Components of Digital Weight Transmitters

In Digital Weight Transmitters there are some key components used every component has a specific function in the weighing process makes it inevitable.

Load cells

Load cells are the key sensors for converting mechanical weight (force) into electrical signals. These load cells come in various types such as strain gauge, piezoelectric and capacitive.

Signal conditioning circuitry

Signal conditioning circuitry intensifies, digitizes and filters the raw signals from the load cell making it sure to get the ideal performance & accuracy. This component reduces the noise intervention and increases the overall signal-to-noise ratio.

Digital processing unit

The digital processing unit processes the weight data in a digitized manner & performs tasks like calibration, error correction & linearization. Advanced algorithms are attached within the processing unit to enable real-time adjustment & improvisation to get consistence & reliable data.

Communication interfaces

The best part about modern digital weight transmitters is their adaptability & flexibility to communicate with external systems & devices for seamless integration. General interfaces such as RS-232, RS-485, Ethernet, and wireless communication such as Wi-Fi, and Bluetooth make it easier to process data transfer to Programmable Logical Control (PLC), Human human-machine interface (HMI), Supervisory Control And Data Acquisition (SCADA)

Types of Digital Weight Transmitters

There are mainly three types of digital weight transmitters available in the market to use for different technologies and fulfil specific application requirements.

Analog-to-digital converters (ADC)

These types of Transmitters are best suited for demanding environments where high resolution and accuracy are paramount. These ADC base transmitters convert analog weight signals into a digital format using precise analogue-to-digital conversion techniques.

Digital signal processors (DSP)

These types of transmitters are ideal where data analysis, noise reduction & real-time filtering are essential. DSP-based transmitters integrate digital signal processing algorithms to enhance their signal quality & stability.

Microcontrollers

These types of transmitters are ideal where cost-effectiveness and compact solutions are needed additionally it is used in portable & embedded weighing applications.

How Digital Weight Transmitters Work

Digital weight transmitters incorporate sophisticated algorithms and techniques to have trustworthiness & precise weight measurement

Signal conversion process

The signal conversion process consists acquisition of analog weight signals from load cells then those signals are Amplified, filtered, and digitized by the signal conditioning circuitry the digitized data is processed in a digital processing unit where linearization and calibration algorithms are applied to reimburse for environment factors & non-linearities.

Calibration procedures

Calibration is a crucial step when it comes to accuracy & reliability in digital weight transmitters. During the calibration process weights are applied to the system and in response we compared the transmitter’s expected values. Any inconsistencies are corrected through calibration adjustments to maintain traceable & consistent measurements.

Data transmission protocols

To communicate with external devices & systems digital weight transmitters facilitate various data transmission protocols like Modbus RTU (Remote Terminal Unit) or MQTT (Message Queuing Telemetry Transport) for IOT (Internet of Things) Applications. This protocol helps seamless integration & interoperability for remote monitoring & control.

Advantages of Digital Weight Transmitters

Digital weight transmitters have several advantages compared to analog transmitters making it the first choice for modern weighing systems.

Accuracy and precision

Advanced signal processing algorithms and calibration techniques ensure unparalleled accuracy and precision. Accurate and reliable repeatable measurements can be obtained in challenging environments where temperature and vibration are volatile.

Flexibility and customization

Flexibility and customization options can be easily made in a digital weight transmitter. Flexibility in terms of users can adapt to different devices with their specific requirements. Features like adjusting filter settings, communication parameters, and scaling factors. It is easy to configure in different applications.

Remote monitoring capabilities

With the remote monitoring capabilities digital weight transmitter enhances operational efficiency and safety. With real-time data connectivity and reporting users can take proactive measures and troubleshooting.

Factors to Consider When Choosing a Digital Weight Transmitter

When you decide to select the appropriate digital weight transmitter make sure you go through with the following key points for consideration and better decision making.

Accuracy requirements

Accuracy requirements play an important role in finalizing the suitable digital weight transmitter. Based on high-end accuracy end application one can choose the transmitter for laboratory applications, robust industrial weighing, and heavy-duty environments.

Environmental conditions

Different environmental conditions affect the performance of digital weight transmitters so make sure you consider factors like temperature variations, humidity levels, and exposure to dust or corrosive substances. These factors can impact the performance of shelf-life of the device. Always consider a transmitter with robust construction and environmental protection ratings enabling it to operate in harsh conditions.

Communication protocols compatibility

Make sure your selected digital weight transmitter is compatible with existing communication protocols and systems. Modern design and development integrated with PLCs, SCADA systems and cloud-based platforms. Common protocols like Modbus and, the Profibus of Ethernet/IP make it easier for installation and integration which eventually results in minimizing the downtime and comparability issues.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for maximizing the performance and lifespan of digital weight transmitters.

Proper mounting procedures

Improper mounting may result in unstable surfaces, vibration shocks, and measurement errors so always take the operational manual from the original equipment manufacturer for best recommended suggestions for better performance and high accuracy.

Regular calibration checks

Regular calibration check avoids the wear and tear of the products and minimizes the maintenance cost. Calibration tests should be done using certified weights traceable to national standards, making sure the users follow the established procedure and recommendations provided by the manufacturer.

Troubleshooting common issues

Proactive action for identifying and addressing common troubleshooting issues helps you prevent downtime and expensive repair costs. Always go through the troubleshooting guidelines and manual provided by the manufacturer it will help the smooth workflow and better consistency for quality products on a consistence basis.

Industry Applications of Digital Weight Transmitters

Digital weight transmitter makes their place in varied applications for their efficiency, precision and accurate weight measurement.

Industrial automation

Digital weight transmitter plays a pivotal role in Industrial automation. It ensures quality in process control and batch manufacturing.

Process control systems

In process control systems like chemical processing, food and beverage, pharmaceutical digital weight transmitter is an integral component. Providing real-time weight data and on-time feedback it helps process control to maintain the tight quality guidelines.

Logistics and shipping

In Cargo Industries, weighing inventory management, and vehicle load industry this digital weight transmitter helps to optimise load distribution, prevent it from overloading and ensure compliance with weight regulations, enhance safety precautions and efficiency in transport operations.

Future Trends in Digital Weight Transmitters

With the advancement in technology like Wi-Fi, IoT, cloud cloud-based platforms demand for digital weight transmitters will increase over some time.

Integration with IoT technology

IoT is the future of the industry and enables enhanced connectivity, data analysis, and predictive maintenance. The best part is user can diagnose the problem remotely and implement the maintenance strategy for better performance by taking predictive measures.

Artificial intelligence enhancements

With the increased use of AI (Artificial Intelligence) algorithms the digital weight transmitter has also advanced in nature. Ai-based transmitters identify future trends by collecting and measuring the data analysis and help in better decision-making for the highest quality product processing.

Miniaturization and portability

A new era started with an advanced digital weight transmitter in a portable model with smaller, lighter and pocket size. The compact device is ideal for space limitations and easy mobility. Handheld scales, portable weighing systems and field measurements are a few such applications it.

Case Studies: Real-Life Examples

Real-life case studies prove digital weight transmitters' suitability, flexibility and adaptability in various applications.

Case study 1: Manufacturing sector

One of the pharmaceutical companies that is into the liquid filling line process installed and set up a digital weight transmitter. The company wants to measure the weight of each container in real time, The transmitter ensures consistent product quality and reduces waste resulting company saving cost and manpower and maintaining the stringent quality guidelines.

Case study 2: Transportation industry

One of the logistics companies has deployed a digital weight transmitter in its fleet of trucks to monitor cargo weight and distribution during transportation. Incorporating a transmitter with on-board telematics Systems Company improves load efficiency, reduces fuel consumption adheres to weight regulation helps operational efficiency and profitability.

Case Study 3: Healthcare applications

One of the well-known healthcare companies has installed a digital weight transmitter in their medical scales for weighing patients’s weight, monitoring body weight changes and administrating the medication dosages accurately. These devices provided healthcare professionals with reliable and precise weight measurements of Patients.

Based on real-time and data analysis healthcare professionals facilitate personalized patient care and treatment plans.

Comparison with Traditional Weight Transmitters

Performance differences

Digital weight transmitter has higher accuracy, stability and resolution making it the priority for end users over analog transmitter. With improved and reliable performance it boasts noise-free interference and a challenging environment.

Cost-effectiveness analysis

Digital weight transmitter has higher initial costs compared to analogue transmitters but in the long run, they are cost-saving as it's have improved accuracy, reliability and efficiency. The persistent quality standards and reduced waste, fewer downloads and minimal maintenance cost result in higher return on investment and consistent product quality improving customer experience with seamless product delivery.

Regulatory Compliance and Standards

The advanced digital weight transmitter complies with international standards for maintaining accuracy reliability and legality.

International standards for digital weight transmitters

Digital weight transmitters must comply with international standards and certificates such as OIMl (International Organization of Legal Metrology) and NTEP (National Type Evaluation Program). These standards mean the performance requirements and metrological specifications for varied digital weighing instruments ensuring consistency and traceability in weight measurement.

Calibration certifications

Certificated issued by an accredited calibration laboratory assures the digital weight transmitter with accuracy and reliability. This certification demonstrates the calibration procedure and traceability of national standards and compliance with regulatory requirements and quality assurance standards.

Common Misconceptions about Digital Weight Transmitters

Despite having its wide spectrum adoption and several pros there are still some myths and misconceptions about digital weight transmitters.

Myth debunking

One of the most common myths and misconceptions found in the market is that digital weight transmitters are complex and difficult to calibrate compared to analogue transmitters whereas the new advance developed digital weight transmitter has user-friendly calibre procedure and automated tools that make its calibration quick, easy and accurate.

Future Prospects and Growth Opportunities

As the world is rapidly changing with artificial intelligence, machine learning and cloud-based platforms the need and demand for digital weight transmitters is increasing day by day with various applications and a customised solution.

Market trends analysis

Market trends and analysis for digital weight transmitters are outstanding and it's continuing to grow in upcoming decades. As a few of the industries which are going to rule in the upcoming decades such as manufacturing, healthcare, agriculture, and logistics, the demand ratio is directly proportional to the increase in the demand for digital weight transmitters. Data-driven analysis, approach and innovation will help the market expansion at the global level.

Emerging markets and industries

As time passes more and new industries come into play like renewable energy, e-commerce, and smart agriculture which help and enable the increased demand for digital weight transmitters.

Conclusion

Digital weight transmitters will have a huge impact and revolutionize industrial weighing systems, offering versatility, unparalleled accuracy, and better reliability resulting in higher defect-free production, less maintenance, minimising waste, and consistent product quality for a better customer experience which eventually results in a higher customers retention ratio.

FAQs about Digital Weight Transmitters

1. Can digital weight transmitters be used in hazardous environments?

Safety standards are the first and foremost factor; digital weight transmitters are designed and developed in such a way to meet various safety standards including hazardous environments. Based on needs one can choose an appropriate model with the certificate like ATEX or UL spending upon the application industries and end usage.

2. What are the typical maintenance intervals for digital weight transmitters?

Maintenance internally varies depending on the end product application, challenging environment, OEM recommendation, and usage. Regular maintenance needs to be carried out for a smooth and hassle-free product process. Ideally, you can go with monthly, quarterly, half-yearly to annually based on your product accuracy and consistency.

3. Are there any regulations or standards governing the use of digital weight transmitters in certain industries?

Different industries have different quality and compliance standards based on that you can. Choose the transmitter model for your end use. ISO 9001 stands for stringent quality standards and OIML (International Organization of Legal Metrology) stands for standard weighing instruments in trade.

4. How do digital weight transmitters compare to analog weighing systems in terms of cost-effectiveness?

Digital weight transmitters have higher upfront costs but as time passes it will help you to reduce the wastages, minimum manpower for quality standards, reduce maintenance cost, increase product quality and durability overall digital weight transmitter helps you reduced cost.

5. What are some emerging applications of digital weight transmitters in niche industries?

Global market expansion and emerging industries have come aggressively into the market to prove their existence resulting in increased demand for digital weight transmitter industries like pharmaceutical, food processing, renewable energy, mining and exploration comes into play.

6. What makes Rudrra Sensor Unique from Other Digital Weight Transmitter Manufacturers in the Market?

Rudrra Sensor is one of the leading manufacturers and suppliers of Digital Weight Transmitter in Ahmedabad, Gujarat, India since 2002, backed by 150+ skilled experienced technicians, and 50000+ square feet of infrastructure we can supply devices in a short lead time with optimal product performance & high quality. We have provided the standard as well as tailored solutions to different industries & have supplied digital weigh transmitters to domestic as well as international companies.

Download PDf File

Download PDf File