How satisfied were

you with

Rudrra Sensors??

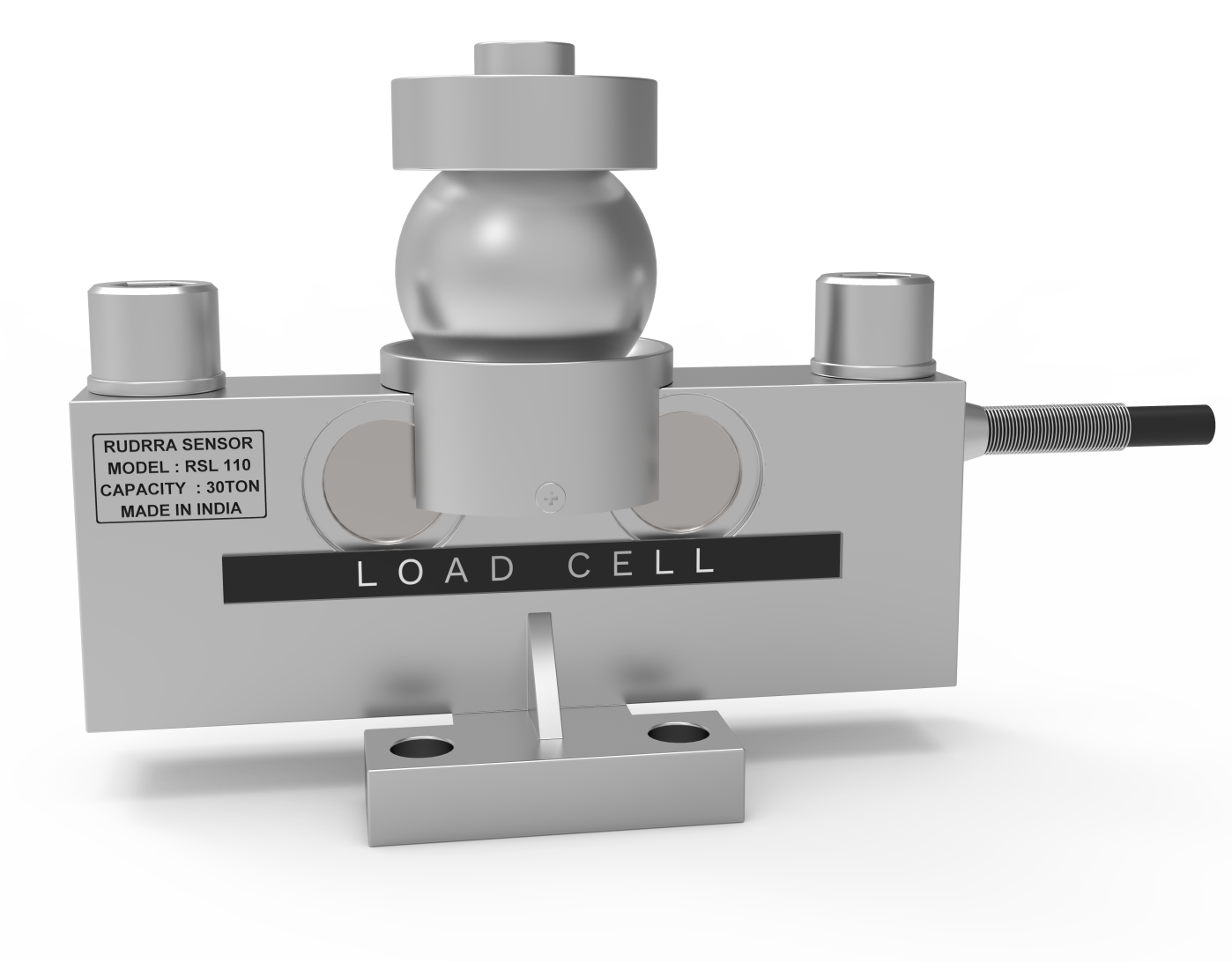

Column Type Load Cell

Buy RS-3 Online in India

While available in a wide range of size possibilities, the RC3 is a single column compression load cell idea that is very resilient despite the fact that it is offered in a single column configuration. Because rocker columns move with the scale deck, the highest potential weighing accuracy may be achieved while the scale deck is in motion. In comparison to the RC1, load cells made of stainless steel that are completely sealed are a more cost-effective option.

Rudrra Sensor's compression load cells are used in a wide range of weighing applications and are made in-house. With its wide range of technology and size options, this multicolumn device may be used in a number of industries and applications. In this case, the RS3 designation refers to the Column Type Load Cell configuration of this product. It is also a self-repairable device that relies on strain gauges to function properly.

This load cell, despite its tiny size, is capable of completing a wide range of activities despite its small size. It is the high-quality stainless steel that is used in their construction that remains unaffected by the rigorous circumstances in which they are made.

ABOUT US

Aside from that, Rudrra Sensors is a leading producer, supplier of high and premium-grade load indicators with both manual and automated tare control options. Because of the way bending beam load cells are constructed, some portions of the load cell body flex or curve in response to the application of a load. Applied Technologies is a leader in the manufacturing of precision load cells, pressure transducers, and load indicators. Load Masters is one of the top manufacturers and suppliers in the world.

Contact us if you have any questions or concerns of any kind.

Features :

There is a broad range of talents available. 7.5 to 300 metric tonnes

The use of stainless steel in the construction of the structure

IP68 is an international standard for complete hermetic seals for environmental protection.

The design is capable of being repaired by the user.

Applicaion :

Scales for measuring the weight of hoppers, tanks, and silos

Vehicles are weighed on scales.

Bridge scales are used to measure the weight of bridges.

Optional :

Digital Load cell

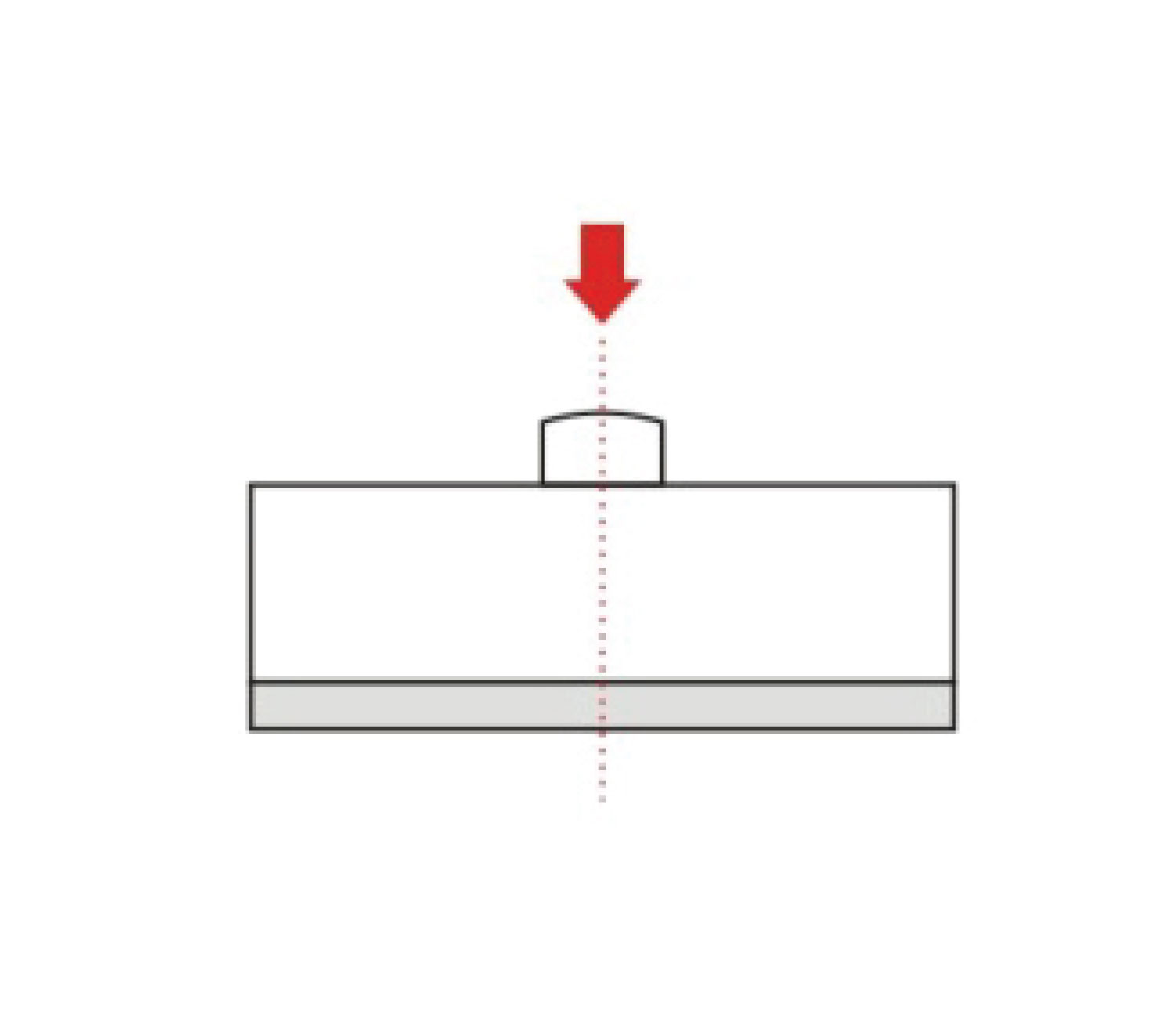

Load Application Layout :

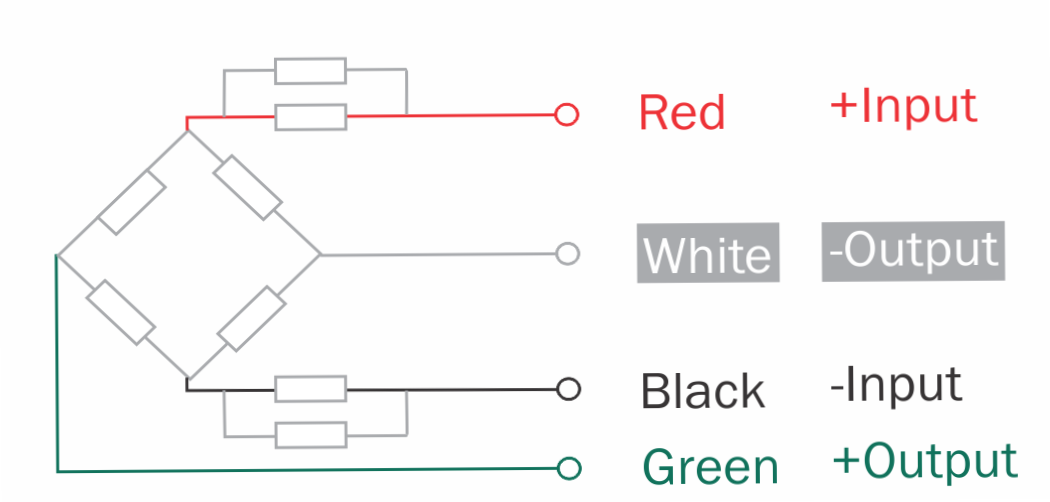

Cable Connection Details :

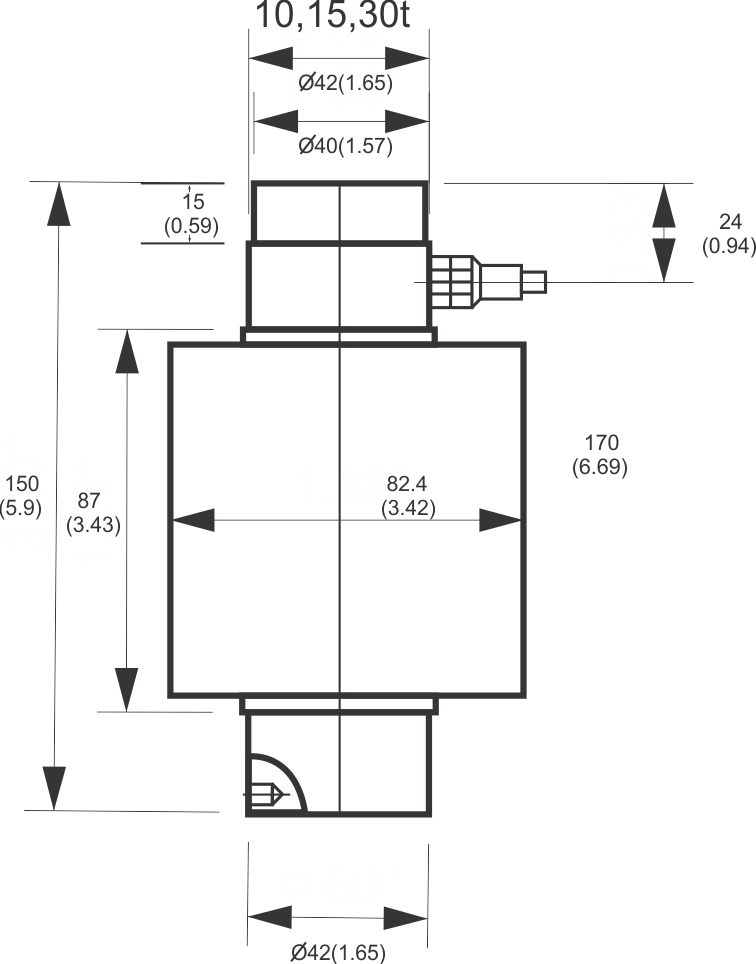

Dimensions :

Capacity/Size | A | B | C | D | E | F | H | K | SR |

10, 20, 30t | 150 | 82 | 40 | 38 | 82 | 34.7 | 41.7 | 8 | 150 |

40, 50, 60t | 170 | 88 | 53 | 47 | 95 | 43 | 53 | 10 | 200 |

Item/Parameter | C3 | Unit |

Rated load (Ton): | 10, 20, 30, 40, 50, 60 | t |

Maximal numbers of load cell verification Intervals (NIc): | 3000 | d |

Minimum load cell Verification intervals Intervals (Vmin): | 0.01 | % of rated load |

Rated output (Cn): | 2.0 + 0.1% | mV/V |

*Combined error: | 0.015 | + % of rated output |

Temperature effect on sensitivity (Tkc): | 0.0012 | + % of rated output °C |

Temperature effect on Zero balance (TkO): | 0.0008 | + % of rated output °C |

Zero balance: | 1.0 | + % of rated output |

Input balance: | 775 + 5 | Ω (Ohms) |

Output resistance (Ro): | 702 + 2 | Ω (Ohms) |

Insulation resistance: | > 5000 | M Ω (Mega-Ohms) |

Safe overload: | 150 | + % of rated capacity |

Ultimate overload: | 300 | + % of rated capacity |

Operating temperature range: | -20 + 70/-20 + 160 | °C / °F |

Recommend excitation: | 5-15 | V(DC or AC) |

Maximum excitation: | 24 | V(DC or AC) |

Material of elastomer: | Stainless Steel | |

Protection class: | IP67/IP68 |

Download PDf File

Download PDf File