How satisfied were

you with

Rudrra Sensors??

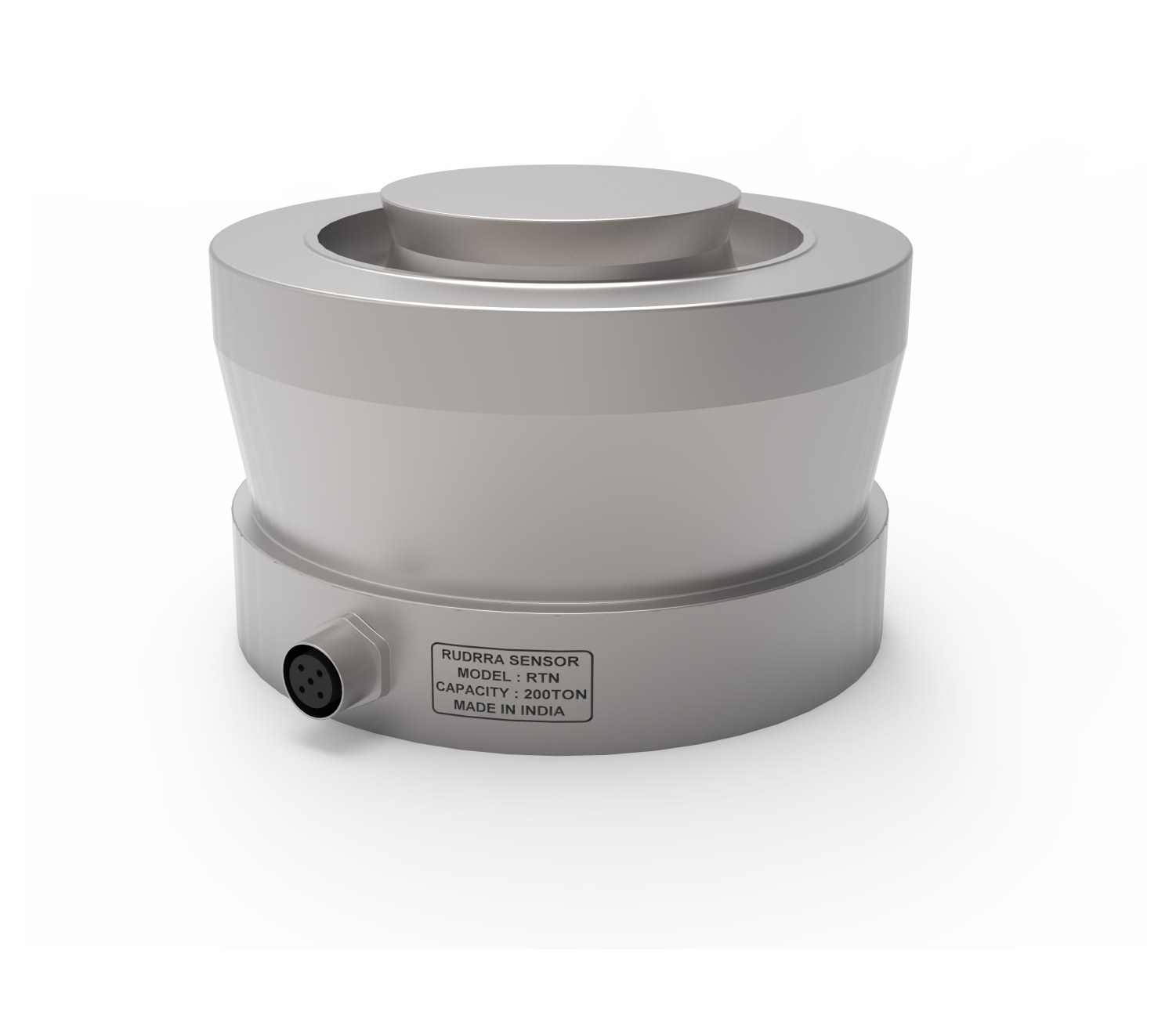

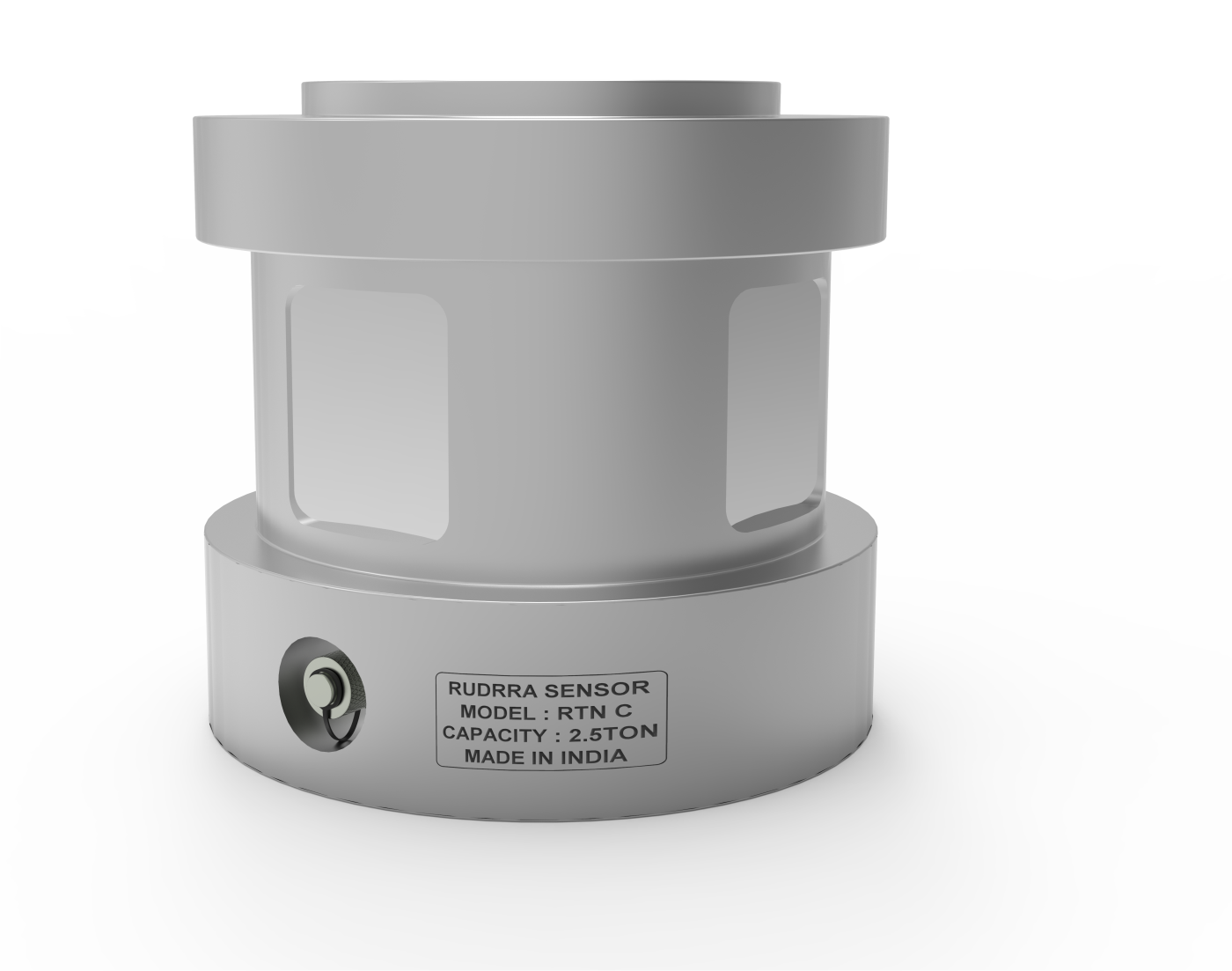

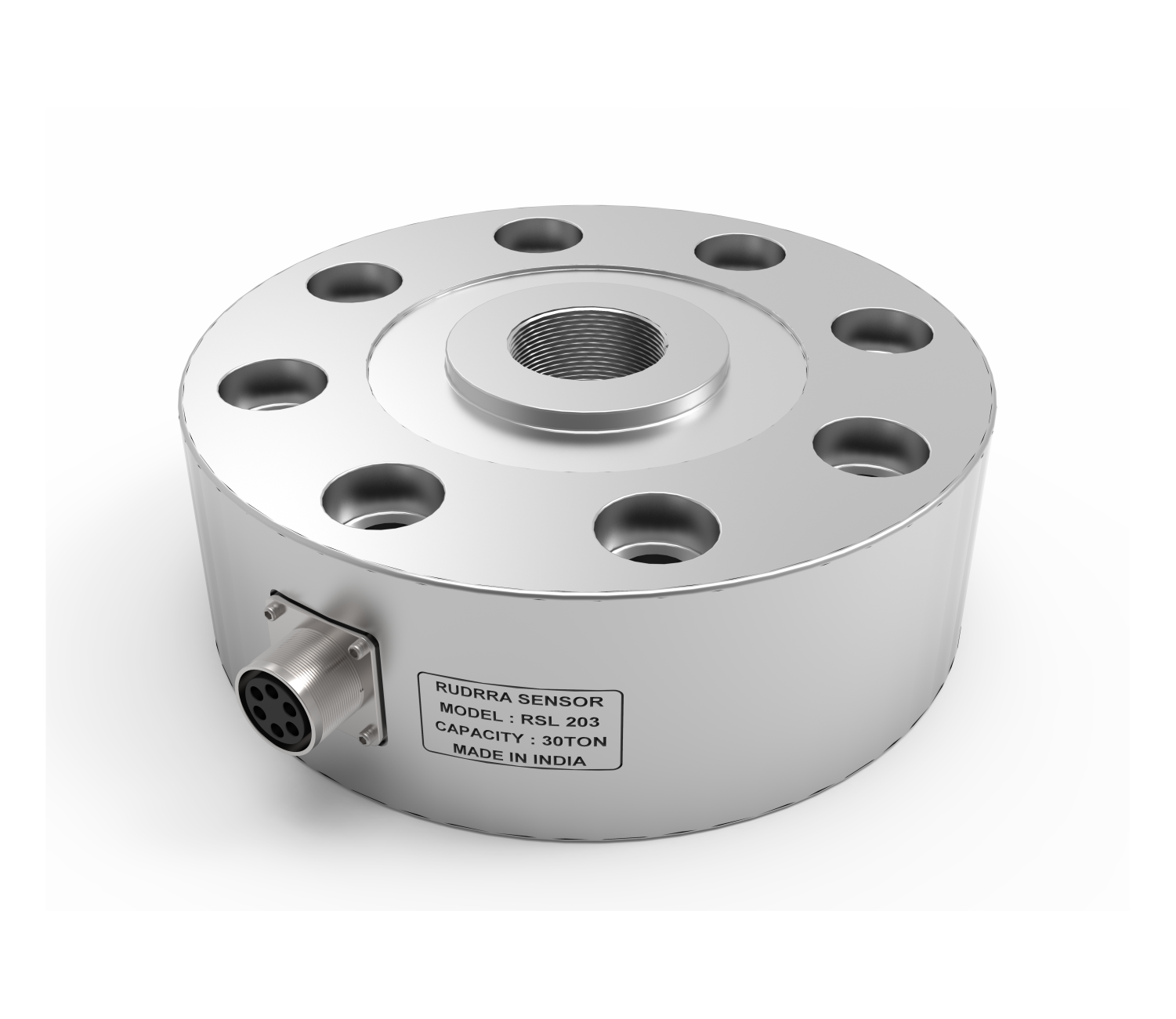

Low profile Compression Load Cell

A compression load cell is one of the most common types of load cells used in the weighing industry. Others, such as tension, beam, and single-point, are examples of such structures. In order to determine the force produced by an item, compression load cells are placed underneath the object that is being weighed or measured. These load cells, in contrast to tension load cells, are only intended to detect the compression of the downward force, not the tension of the descending force. Tensile load cells may also be used to monitor compression in addition to compression gauges.

The internal workings of a compression load cell may have a wide range of variations. For these calculations, it is possible to utilize data taken in shear or bending as well as ring-torsion or column measurements. Despite the fact that they may be used for a number of applications, the most prevalent use for these load cells is in silos and truck scales, both of which are high-capacity static weighing devices, respectively.

Low profile compression load cells, for example, are used in a wide range of industrial applications across a wide range of sectors. The use of low profile compression load cells in industrial applications is becoming increasingly prevalent as the need for such devices grows.

In fact, it is the fundamental objective of this specific load cell, which is being designed for use in a variety of industrial settings. Because of its stainless steel design, this gadget is resistant to corrosive environments. As a result, before Rudrra Sensor's engineers ship low profile compression load cells to customers, they double-check each one to ensure accuracy and efficiency. The load cell is available in a range of sizes and capacities to meet your needs. When it comes to accuracy, it is well-known in the industrial sector. There are a multitude of solutions available, each with a different price tag associated with them.

Prior to dispatch, our professionals extensively inspect and test the goods to verify that it is of high quality. Various capacities and sizes are available for this product. These are well-known for the accuracy with which they perform their duties. All of the technical information, as well as a diagram of the electrical wiring, may be found in the sections below.

ABOUT US

In the field of precision manufactured load cells, pressure transducers, and load indicators, Rudrra Sensors is one of the top manufacturers and suppliers in the world. We give a product that is both innovative and long-lasting, with no negative consequences.

Contact us if you have any questions or concerns of any kind.

Key Feature :

Stainless Steel Material

Light weight in high capacity

Simple instalation

Application :

High Capacity testing machine

Concrete testing machine

Rolling Mill machine

Customized application

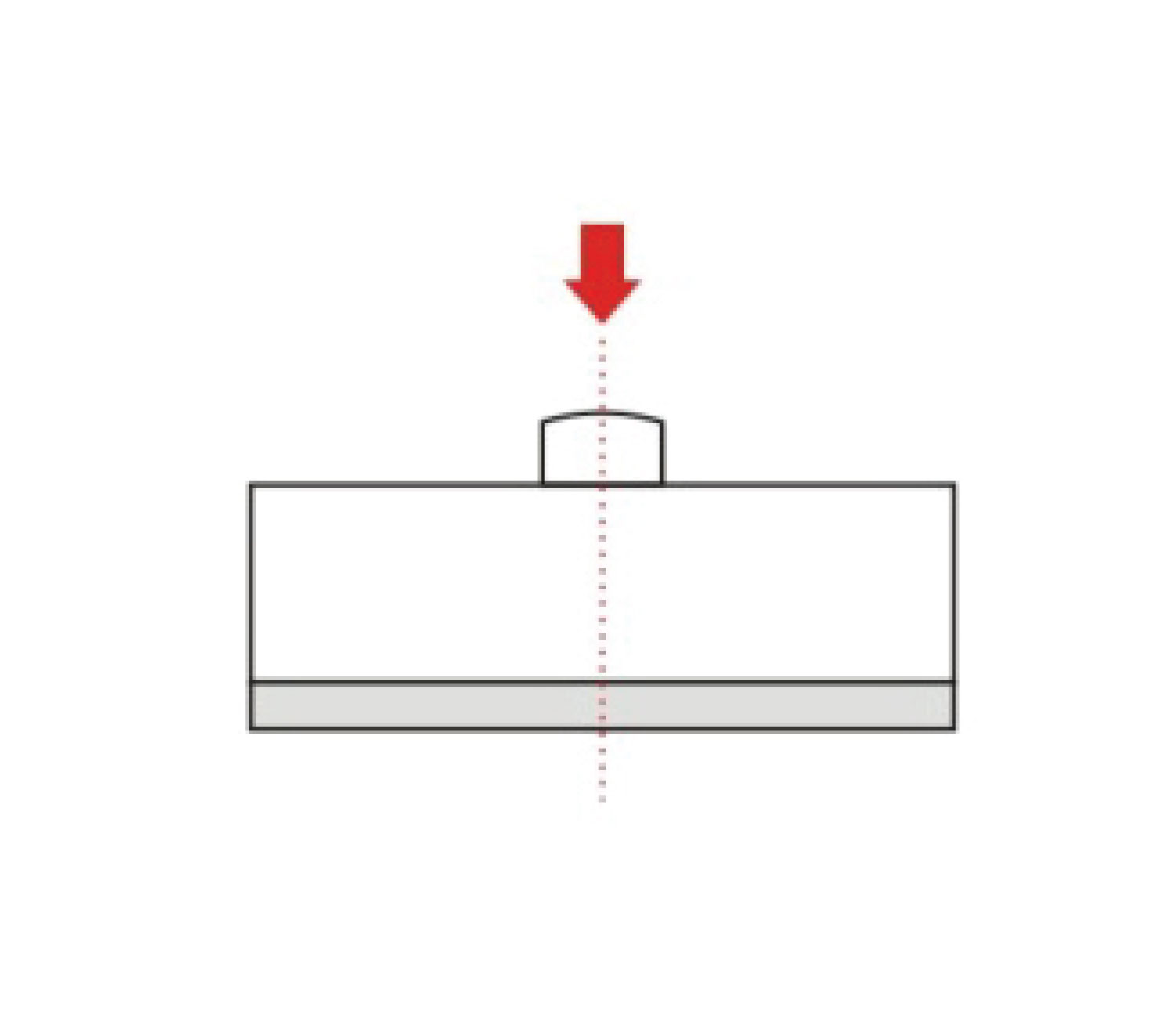

Load Application Layout :

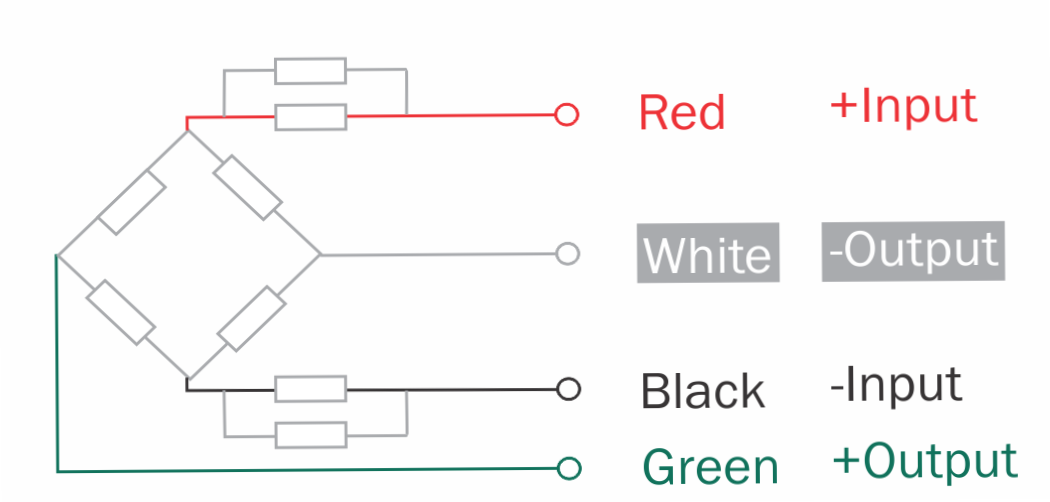

Cable Connection Details :

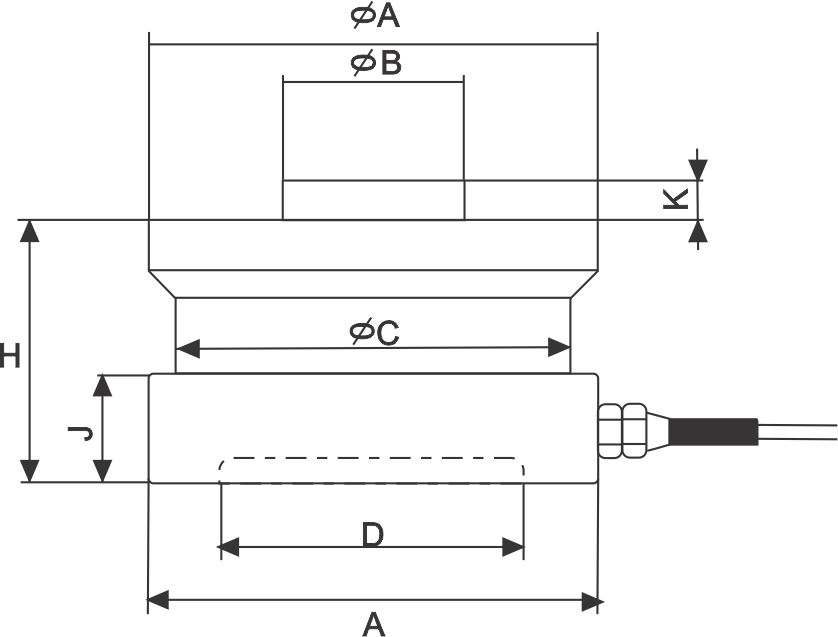

Dimenstions:

Cap | A | B | C | D | H | K | J |

100, 150, 200T | 150 | 70 | 140 | 124 | 80 | 10 | 30 |

Parameter | C3 | Unit |

Rated load (Emax): | 50, 100, 200, 300, 500 | t |

Maximal numbers of load cell verification Intervals (NIc): | 3000 | d |

Minimum load cell Verification intervals Intervals (Vmin): | 0.01 | % of rated load |

Rated output (Cn): | 2.0 + 0.1% | mV/V |

*Combined error: | 0.015 | + % of rated output |

Temperature effect on sensitivity (Tkc): | 0.0012 | + % of rated output °C |

Temperature effect on Zero balance (Tk0): | 0.0008 | + % of rated output °C |

Zero balance: | 1.0 | + % of rated output |

Input balance (Rlc): | 775 + 5 | Ω (Ohms) |

Output resistance (Ro): | 702 + 2 | Ω (Ohms) |

Insulation resistance: | > 5000 | M Ω (Mega-Ohms) |

Safe overload: | 150 | + % of rated capacity |

Ultimate overload: | 300 | + % of rated capacity |

Operating temperature range: | -20 + 70/-20 + 160 | °C / °F |

Recommend excitation: | 5-12 | V(DC or AC) |

Maximum excitation: | 15 | V(DC or AC) |

Material of elastomer: | Alloy steel / Stainless Steel | |

Protection class: | IP67/IP68 |

Download PDf File

Download PDf File