How satisfied were

you with

Rudrra Sensors??

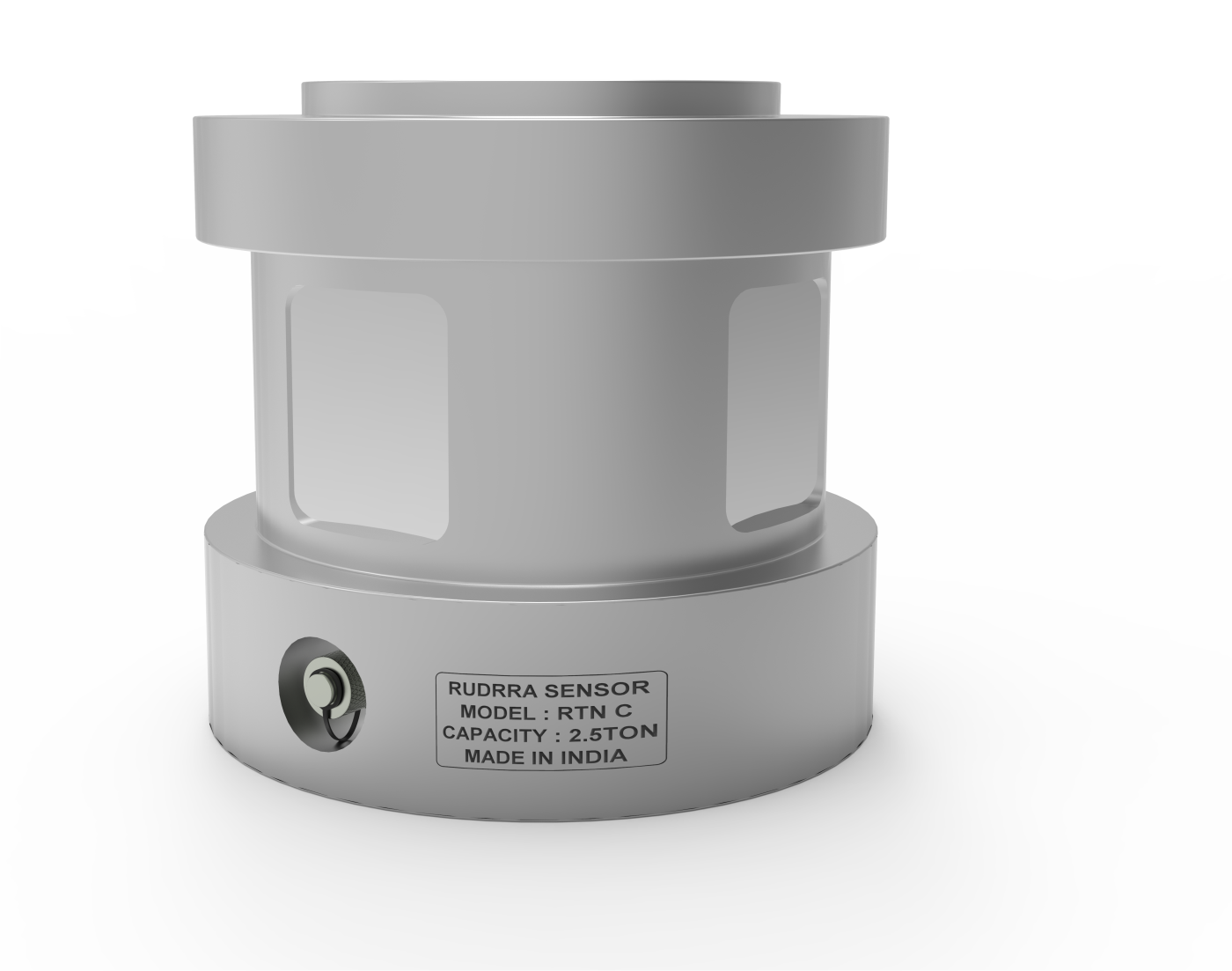

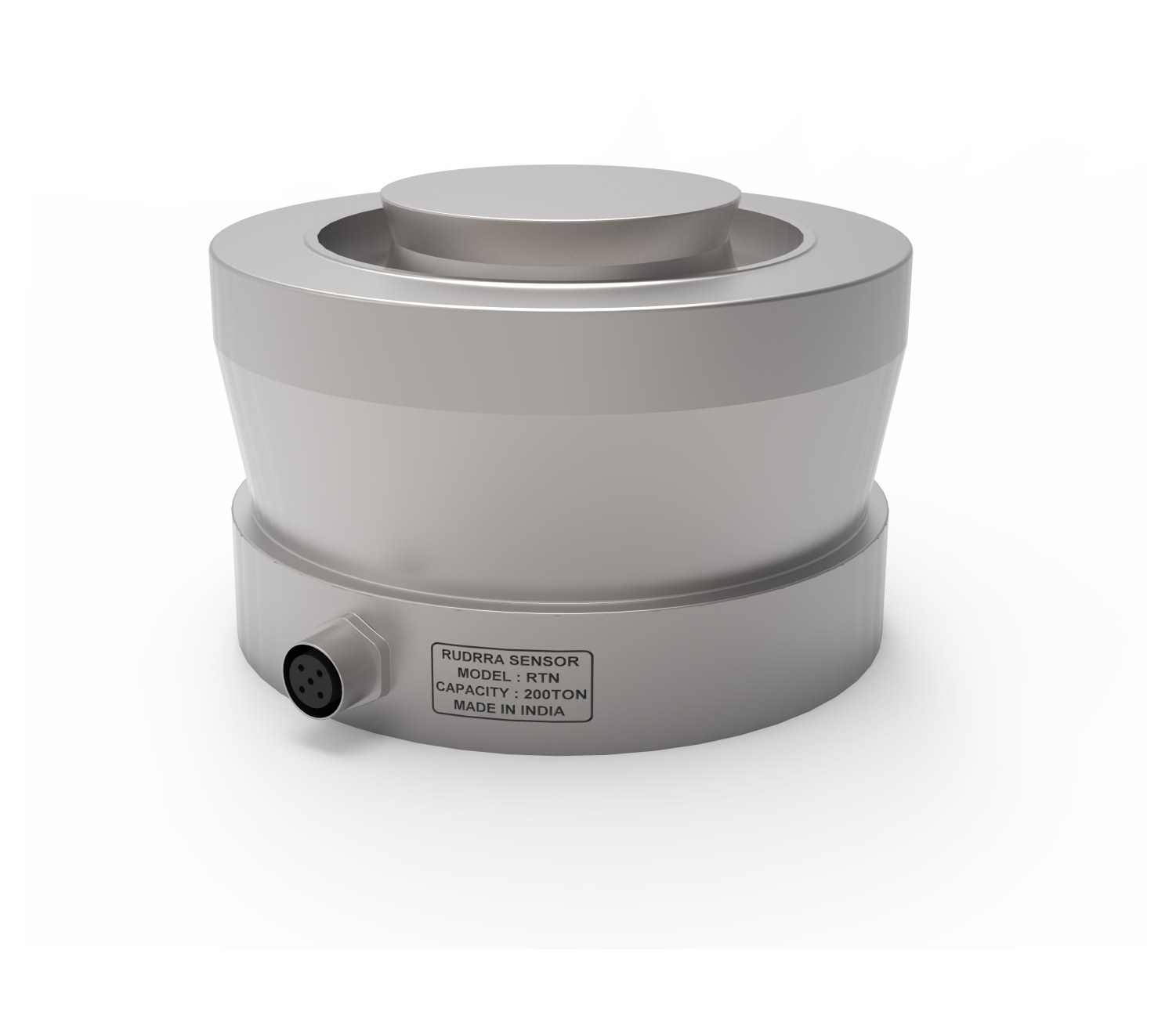

Pile Load Test Load Cell

Best Quality RTN C 500T/1000T in India

A compression load cell's internal workings can be subjected to a wide range of alterations depending on the application. It is possible to make these computations using data acquired in shear or bending tests, as well as ring-torsion or column measurements, among other methods. The most prevalent uses for static weighing systems are silos and truck scales, both of which are high-capacity static weighing systems with high capacity.

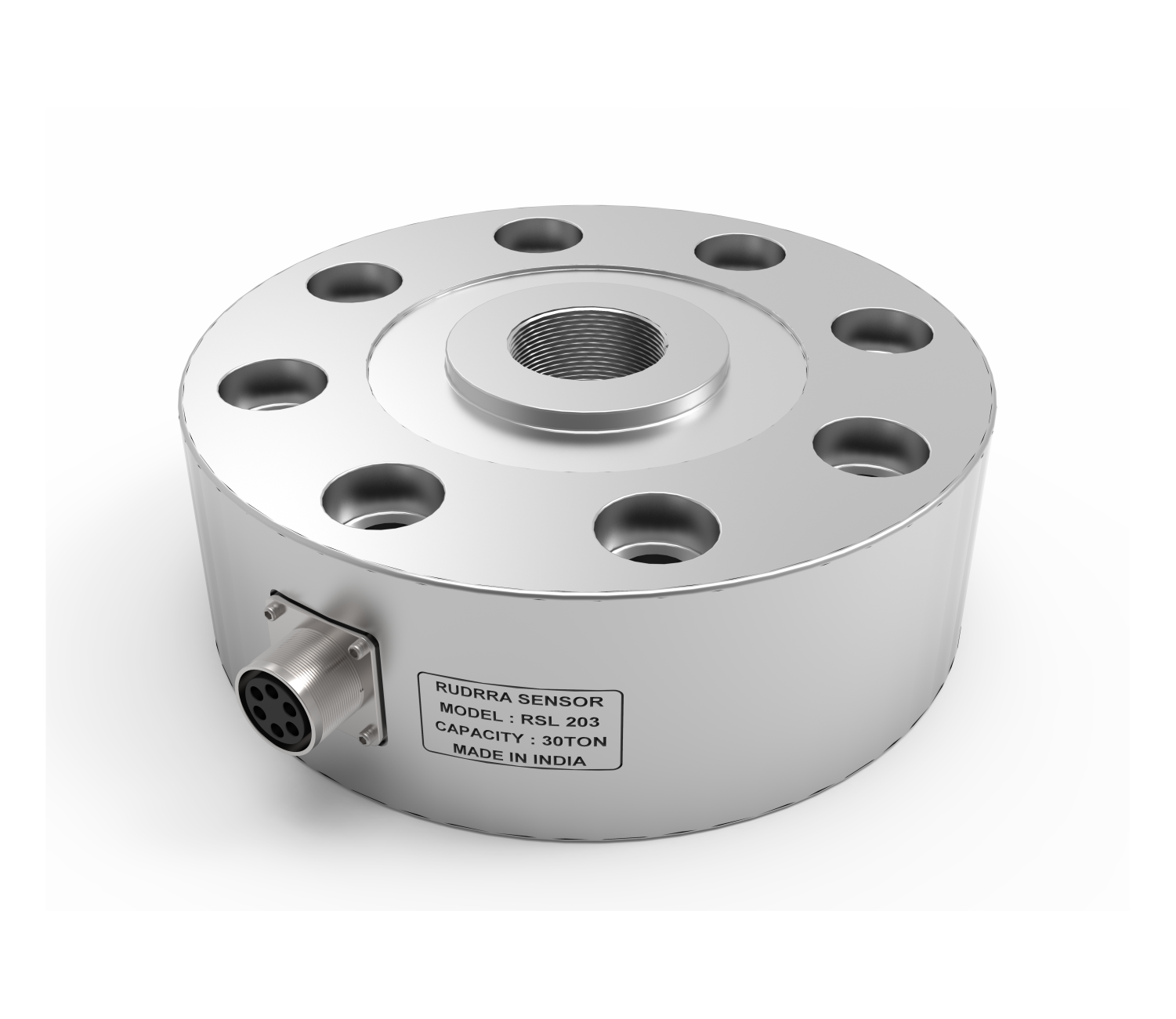

Load cells that measure strain includes the resistive strain gauge load cell type ELC-150S-H and the resistive strain gauge load cell type ELC-150S. In addition to other things, it is primarily used in the measurement of extremely large compressive loads or axial forces. As a result of its versatility, the load cell is commonly used in pile testing applications.

In particular, the ELC-210S is a wonderful fit for this specific load cell in terms of performance. The material's high resistance to external forces makes it less susceptible to problems caused by dust, moisture, and other potentially harmful environmental conditions than other materials. In addition, it allows for less stringent mounting alignment, which reduces the likelihood of reading error while also extending the fatigue life of the device.

ABOUT US :

Furthermore, Rudrra Sensors manufactures, distributes and provides support for high- and premium-grade load indicators, which are capable of being controlled manually or automatically through the use of a tare control system. It is necessary to bend or curve some elements of the load cell body due to the way bending beam load cells are created, and this is due to the way they are constructed. Precision load cells, pressure transducers, and load indicators are all manufactured by our company, which is a leader in the industry. If you're looking to purchase RTN C 500T/1000T, you can do so on our website.

Rudrra Sensors is one of the world's leading producers and providers of load cells and indicators. We provide a product that is both unique and long-lasting, and it has no harmful side effects on the environment.

Key Feature :

Alloy Steel Material & Rugged & robust construction

High capacity & suit harsh and severe industrial enviroment.

Simple installation

Application :

High Capacity testing machine

Concrete testing machine

Rolling Mill machine & compressive load measurement between structural members.

Pile Testing and measurement of thrust of rocks.

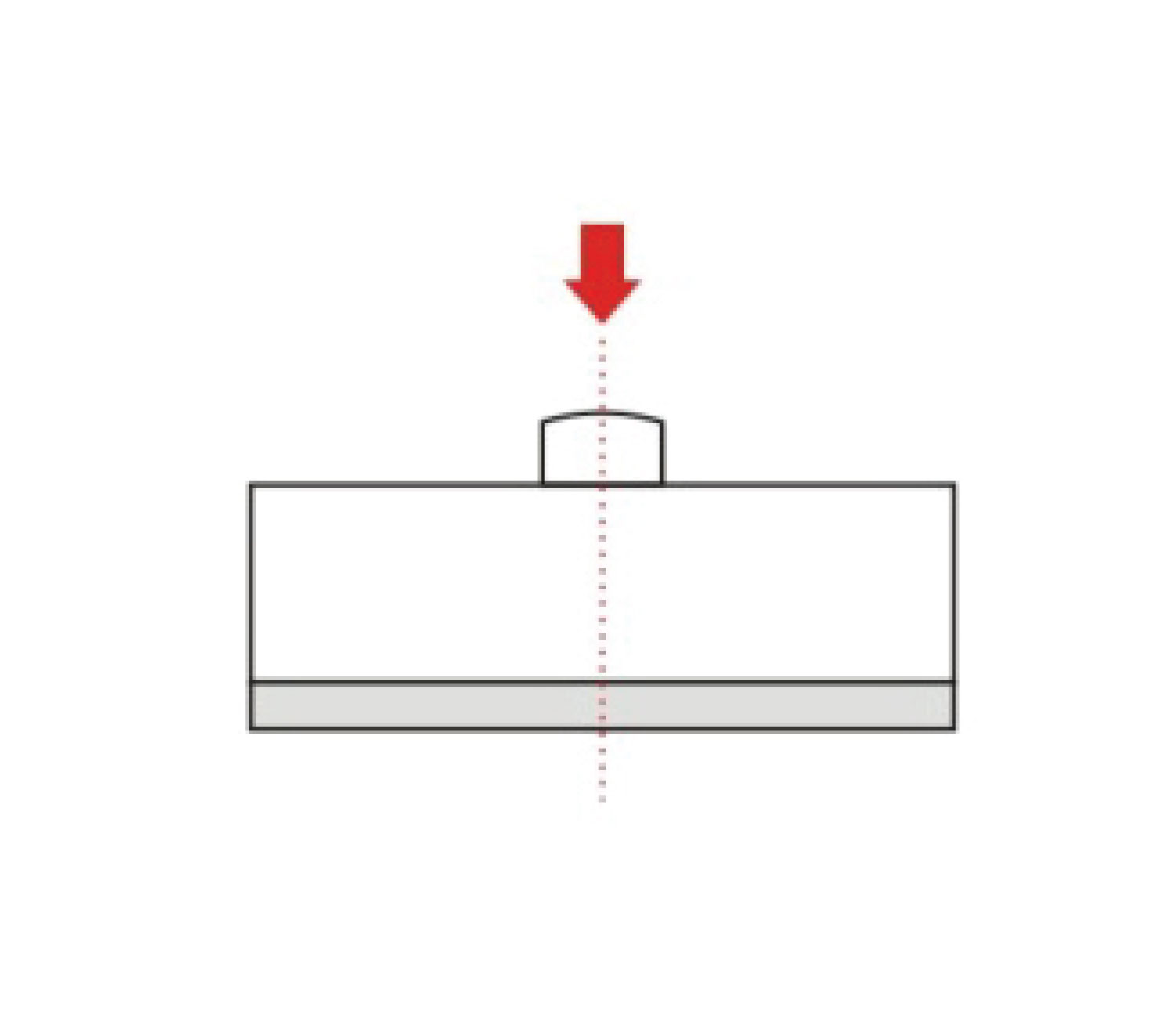

Load Application Layout :

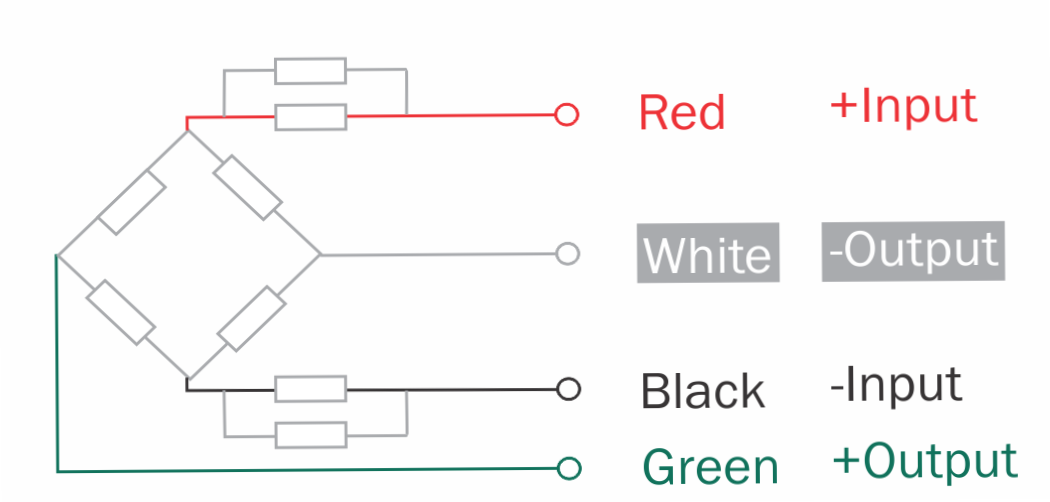

Wiring Schematic Diagram :

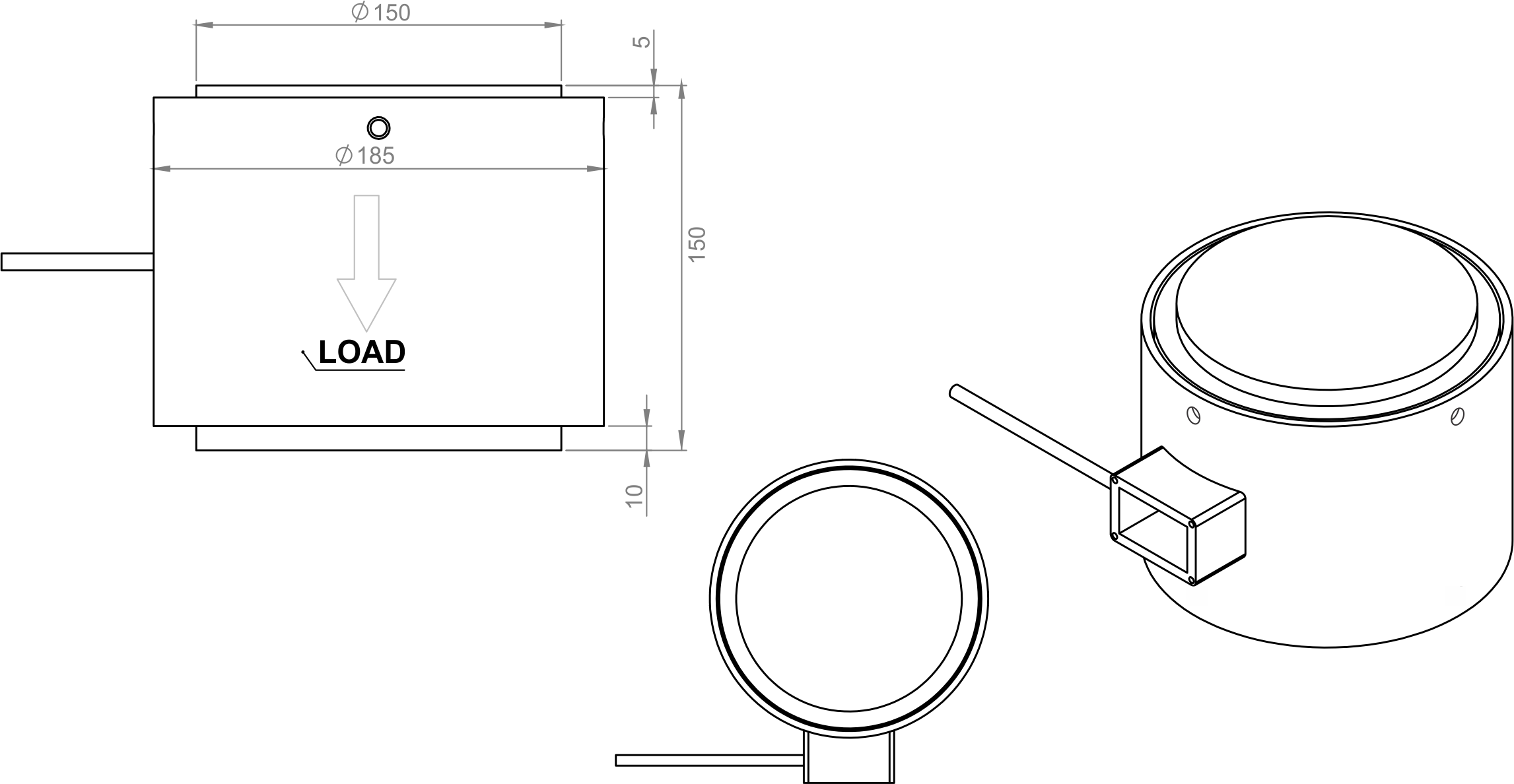

Dimension :

Parameter | C2 | Unit |

Rated load (Emax): | 1000, 2000, 3000, 5000,10000 | kN |

Maximal numbers of load cell verification Intervals (NIc): | 3000 | d |

Minimum load cell Verification intervals Intervals (Vmin): | 0.01 | % of rated load |

Rated output (Cn): | 1.5 + 10% | mV/V |

*Combined error: | 0.015 | + - % of rated output |

Temperature effect on sensitivity (Tkc): | 0.012 | + - % of rated output °C |

Temperature effect on Zero balance (Tk0): | 0.008 | + - % of rated output °C |

Zero balance: | 1.0 | + - % of rated output |

Input balance (Rlc): | 775 + 10 | Ω (Ohms) |

Output resistance (Ro): | 700 + 5 | Ω (Ohms) |

Insulation resistance: | > 5000 | M Ω (Mega-Ohms) |

Safe overload: | 120 | + - % of rated capacity |

Ultimate overload: | 300 | + - % of rated capacity |

Operating temperature range: | -20 + 70 / -20 + 160 | °C / °F |

Recommend excitation: | 5-12 | V(DC or AC) |

Maximum excitation: | 15 | V(DC or AC) |

Material of elastomer: | Alloy steel | |

Protection class: | IP67 |

Download PDf File

Download PDf File