How satisfied were

you with

Rudrra Sensors??

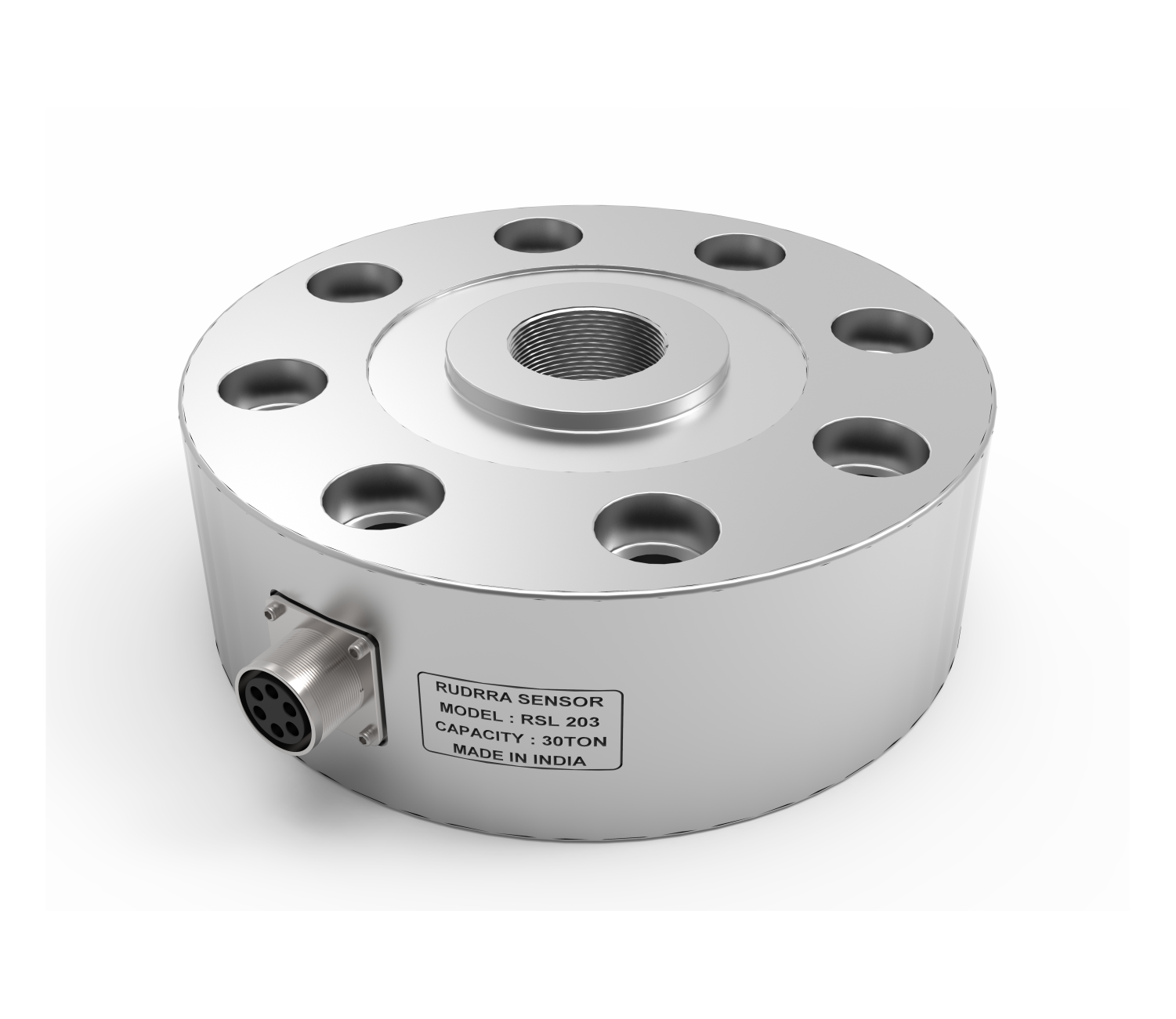

Pan Cake Load Cell

The Pancake Load Cell (aka Universal Load Cell) category is built for Endurance, Off-Center Loading, or Inline applications. Pancake Load Cells represent one of the more common designs offered for force measurement applications because their low profile can be installed within limited real estate

Pancake, canister-style, or universal load cells have a central threaded hole for measuring loads in either tension or compression. These force transducers are used in applications needing high endurance, high fatigue life, or high-capacity in-line measurements such as load cell for tanks weighing system, tablet compression force, or injection molding clamping force applications. They are also highly resistant to off-axis loading.

Pancake Load Cells are available in a wide capacity range from 25 lbs to 1,000,000 pounds, in both Stainless Steel or Anodized Aluminum flexure, utilizing metal foil strain gauge technology. These pancake-type load cells provide a compact design, achieving accurate measurements in both tension and compression. Options such are in-line signal conditioned amplifier and/or TEDS / IEEE 1451.4 are also available.

How it Works

Pancake load cells are designed with bonded foil strain gages to allow for resistance in challenging circumstances like higher temperature environments. Pancake load cells have a dual-diaphragm design that provides excellent off-axis performance.Pancake load cells can be designed and constructed with welded stainless steel or aluminum and have a threaded thru-hole with standard-setting and configurations that allow for the use of standard bolt diameters. Depending on the requirements of the buyer and the manufacturer from which the pancake load cell is to be produced, special threads or metric threads and mounting holes can be added to the pancake load cells being ordered.

Pancake load cells are 0.03% to 0.10% accurate for full-scale output, and they can come with high-level analog voltage, analog current, or digital output according to the specification of the buyer.

Most high-level pancake load cells have internal signal conditioners with proprietary electronics. Units of these load cells, regardless of the type of output, are built with some form of the standard electrical receptacle.

Pancake load cells can come in several designs like high-accuracy, tension-compression, fatigue-rated, precision, and coiled tubing injector pancake load cells, and they are built for endurance, off-center loading, and inline applications.

The tension and compression pancake load cells are designed to measure forces in both tension and compression with high accuracy and feature a low-profile design. Certain pancake compression load cells measure forces compression-only and usually have a digital or analog output. Lastly, fatigue pancake load cells measure forces in tension and compression and are usually used for long-term cycle testing.

Pancake Load Cells at Rudrra Sensor

We are the leading manufacturer and supplier of Pan Cake load cells. Backed by the years of experience and the dedicated expert professionals we have reached in this niche. We are counted as the leader in the industries. These are fabricated using high-quality stainless steel and other raw material. It is known for its precise measuring. It is quite easy to install and use. It is available in different models having different technical specifications. It is accessible in the smallest size 0.1 kg up to 1500 ton weight capacity. Also, the clients can acquire it from us in customized designs as per their specific needs. Our products are appreciated by users because of their proper working and advantageous economical prices. It is highly utilized for immense weighing applications, force measuring, and environmental & industrial harsh applications

Features of Pan Cake Load Cells are:

- Rigid and tough body

- Easy to install and operate

- User friendly most suitable designs

Advantage and disadvantages of pancake load cell

According to the above, we can know the advantage and disadvantages of the pancake load cell.

Advantage :

Strong unbalanced loading resistance performance and lateral loading capacity, high overload capacity, without being affected by the loading point and supporting edge, even stress releasing, good linearity, can be fixed and not rotate.

Disadvantage :

Difficult mechanical processing, high manufacturing cost, great inherent lag, and difficulty to be controlled.

We are the leading manufacturer and supplier of Pan Cake load cell. Backed by the years of experience and the dedicated expert professionals we have reached at this niche. We are counted in the leader in the industries. These are fabricated using high quality stainless steel and other raw material. It is known for its precise measuring. It is quite easy to install and use. It is available in different models having different technical specifications.

The accessible in the smallest size 0.1 kg up to 1500 ton weight capacity. Also the clients can also acquire it from us in customized designs as per their specific need. Our products are appreciated by users because of its proper working and advantageous economical prices. It is highly utilized for immense weighing applications, force measuring and environmental & industrial harsh applications.

Features of Pan cake Load Cells are :

Rigid and tough body

Easy to install and operate

User friendly most suitable designs