How satisfied were

you with

Rudrra Sensors??

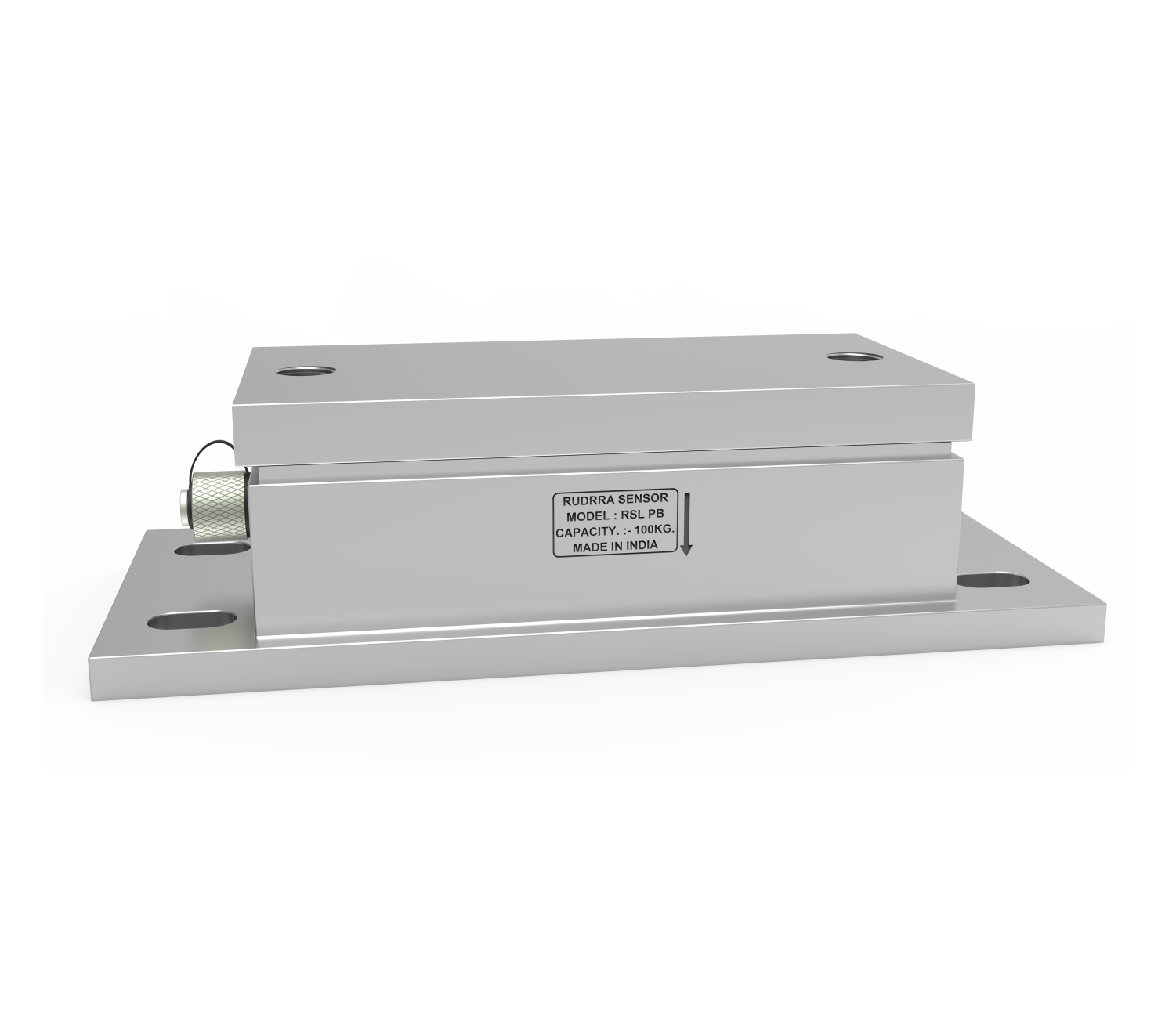

Rotogravure Load Cell

Buy Best RS L Online in India

The load cell used for web tension management is composed of two parts: an outside circle that is stable and flange-covered, and an inner circle that is also stable and flange-covered. RSL testing can be used to determine hydrogen embrittlement, more commonly referred to as hydrogen-induced cracking. This device can be used to test coupons or structural components utilizing ASTM F1624. Step-modified, slow strain-rate testing. It is capable of performing standard ASTM E8. Tensile tests, ASTM F519 200-hour sustained load tests with programmable step loads to rupture, and ASTM G129 slow strain rate tensile tests.

AREA OF USE

There are processing facilities for a wide variety of materials, including web-type materials. The RSL Testing System is capable of testing all specimen geometries specified in ASTM F519, including notched round tensile bars, notched C-rings, and notched square bars. For example, fasteners can be used to conduct product testing on real-world hardware. Utilizing a 1-kip load cell to bend large diameter bolts has a mechanical advantage.

APPLICATION

Using a measuring roller with a 90° horizontal-vertical wrapping angle and a horizontal measuring direction, web tension may be accurately measured.

Speed:The RSL Test Method is a time-efficient method for obtaining precise and reproducible results. The ASTM F 519 Sustained Load Test on notched round bar tensile specimens has been used for decades. This test necessitates 200 hours of exposure to a force with a magnitude equal to 75% of the Fracture Strength. If a specimen does not break during the testing process, it is deemed a success. If it breaks before the 200-hour mark, it has failed. If the Fracture Strength number is greater than 75 percent, the percentage shows how much higher the threshold is and how much lower it is.

Simultaneous testing : Batch-by-batch characterization of materials is achievable thanks to the use of many specimens being tested at once.

Accuracy : Testing for hydrogen embrittlement in a material can be affected by several factors, including the type of coating used, the type of material, how the material is machined, the cleaners used, and many more.

Fast Results - ASTM E1681 KIScc determinations, on the other hand, can take up to 14 months and require 12 specimens because of the necessary run out times to validate the threshold level. The RSL Test Method can yield the same results with five coupons in one to two days.

Rotogravure Load Cell Price

| Model | Rotogravure Load Cell – RS L |

| Price | ₹12500 |

| Capacities | 25 kg, 50 kg |

| Weight | 3 kg, 5 kg |

| Delivery | 2 to 7 Working Days |

Key Features:

Large capacity range.

Anodized aluminium alloy.

Special shielded cable and connector output type of detachable mic.

Off-axis high strength to resist the force.

Designed for web tension measuring.

Easy mounting with clamp.

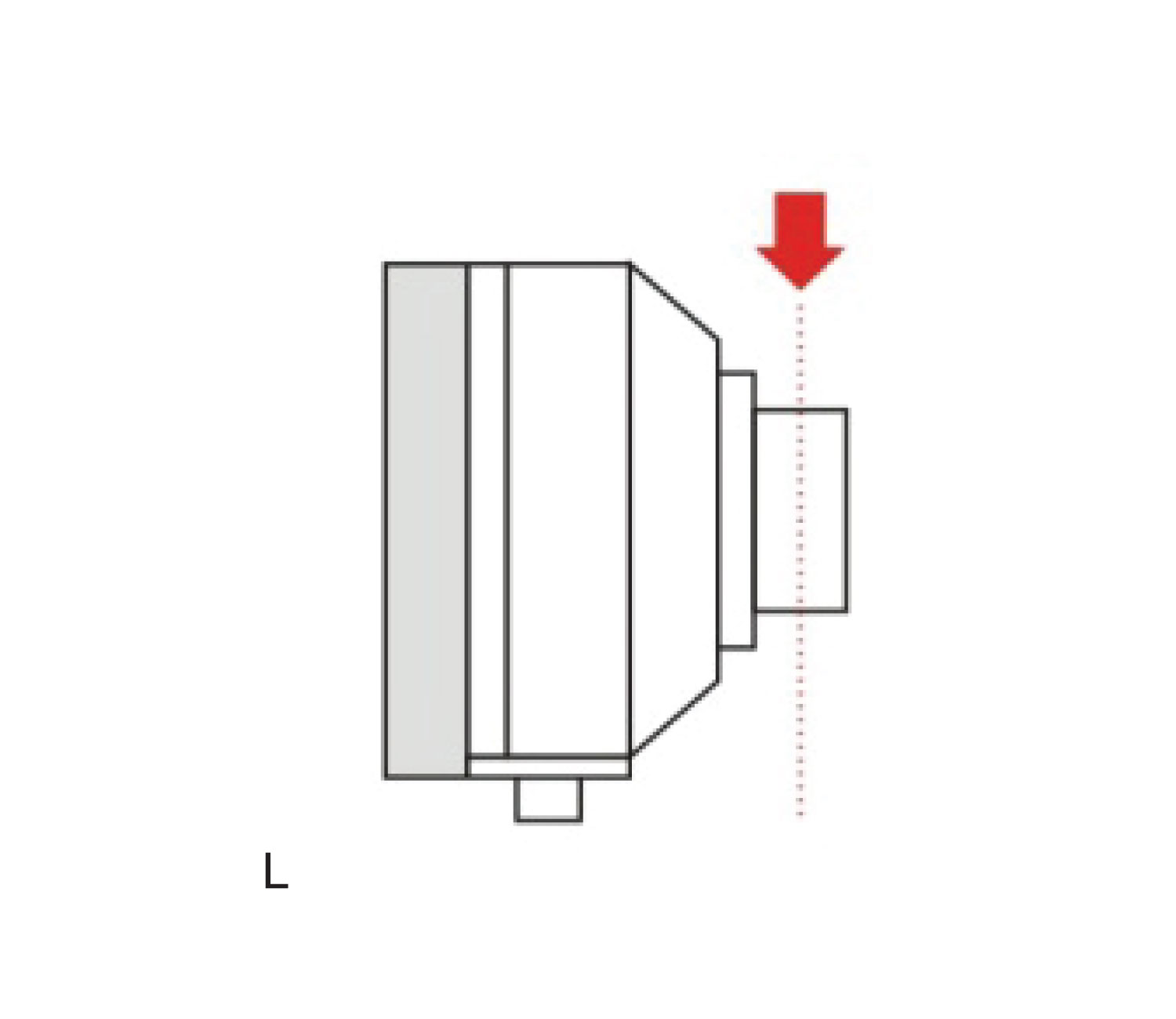

Load Application Layout :

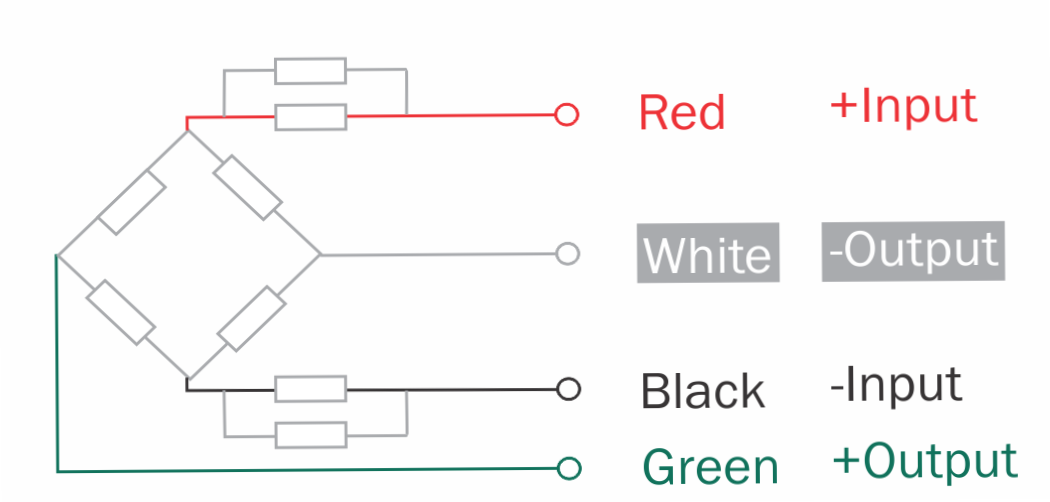

Cable Connection Details :

Dimensions :

Download PDf File

Download PDf File