How satisfied were

you with

Rudrra Sensors??

Web Tension Sensor

What is RS LP?

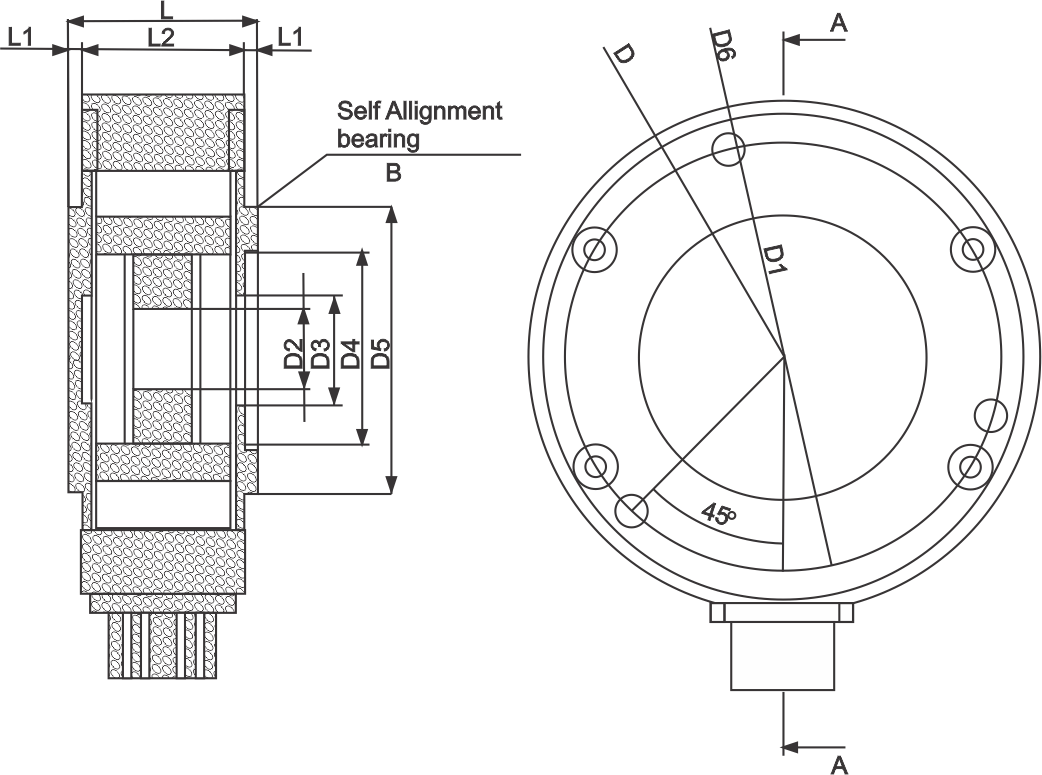

The load cell used for web tension management is composed of a stable outer ring with a flange cover and a centering collar for precision assembly, as well as a centering collar for precision assembly. Ball bearings are installed with their centers aligned by means of an inner ring in the shape of a bidirectional strip. The radial forces generated by the web cause the strain gauges connected together to form a measuring bridge on the inner ring to become unbalanced and unusable. This results in an analogue output signal that is proportional to the tension of the web.

AREA OF USE

A wide range of processing plants, including those that process or finish web-type materials, can benefit from the usage of flange load cells for web tension control. It is critical, in particular in front of processing units that the web is delivered with a constant web tension during the whole transport operation.

APPLICATION

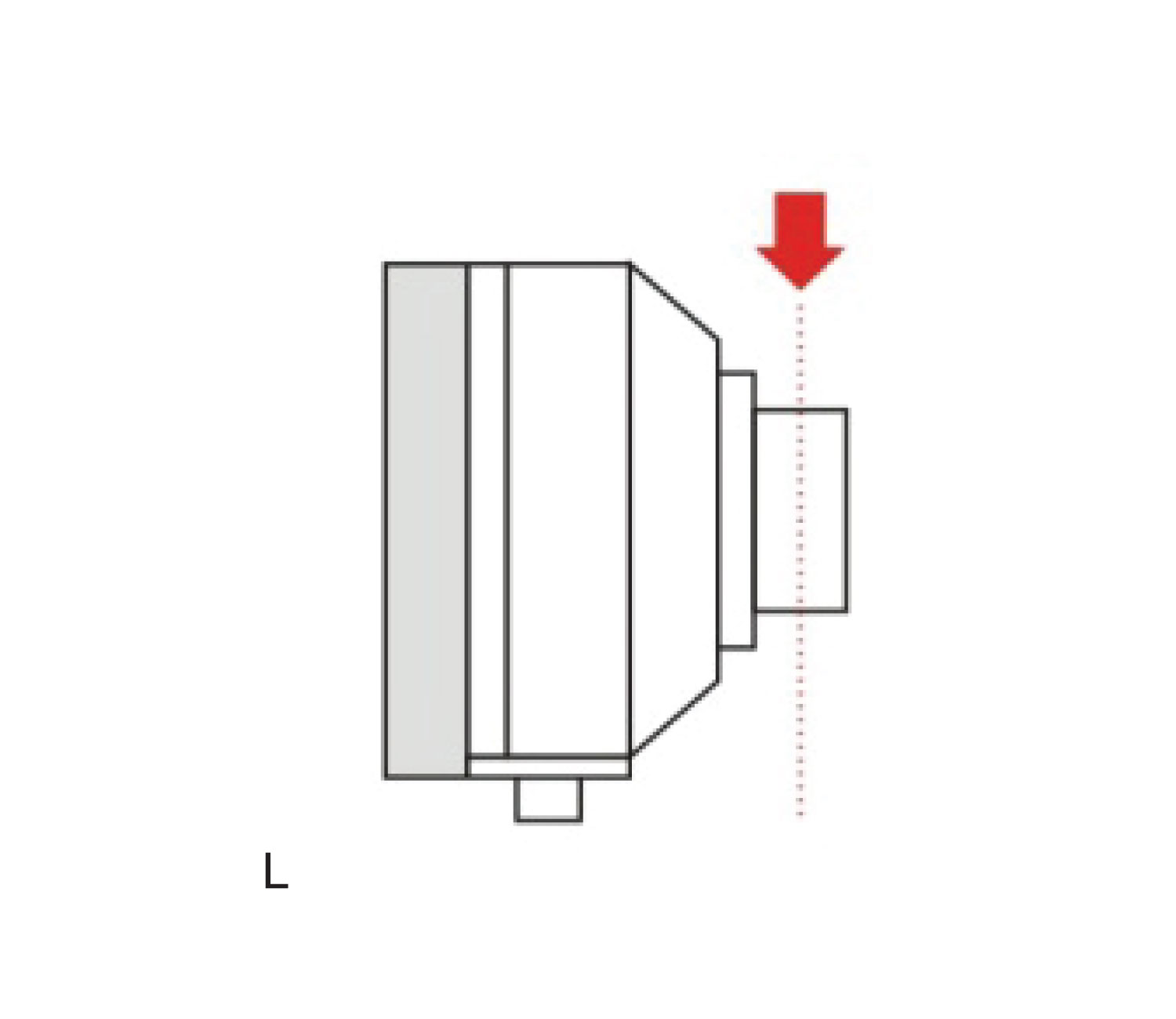

A measuring roller with a 90° horizontal-vertical wrapping angle and a horizontal measuring direction is used to obtain the most precise measurement of web tension. When measuring web tension, the tension sensor must be capable of sensing bearing pressures on both sides of the web at the same time in order to avoid incorrect data caused by the web sliding sideways and an asymmetrical web tension distribution. Whenever possible, load cells that are employed in a closed loop should be located as close to the actuator as is feasible.

ABOUT US

Measurements can be made of all of these things, as well as the tension in the ends of stay ropes, suspension lines, and railway catenary wires. Rudrra Sensors is also manufactures and supplies high and premium grade load indicators that are both manual and automatic tare controls, in addition to providing other services. One of the world's leading manufacturers and providers of precision-machined load cells, pressure transducers, and load indicators is Rudrra Sensors.

We provide a product that is both unique and long-lasting, and it has no harmful side effects on the environment.

Web Tension Sensor Price

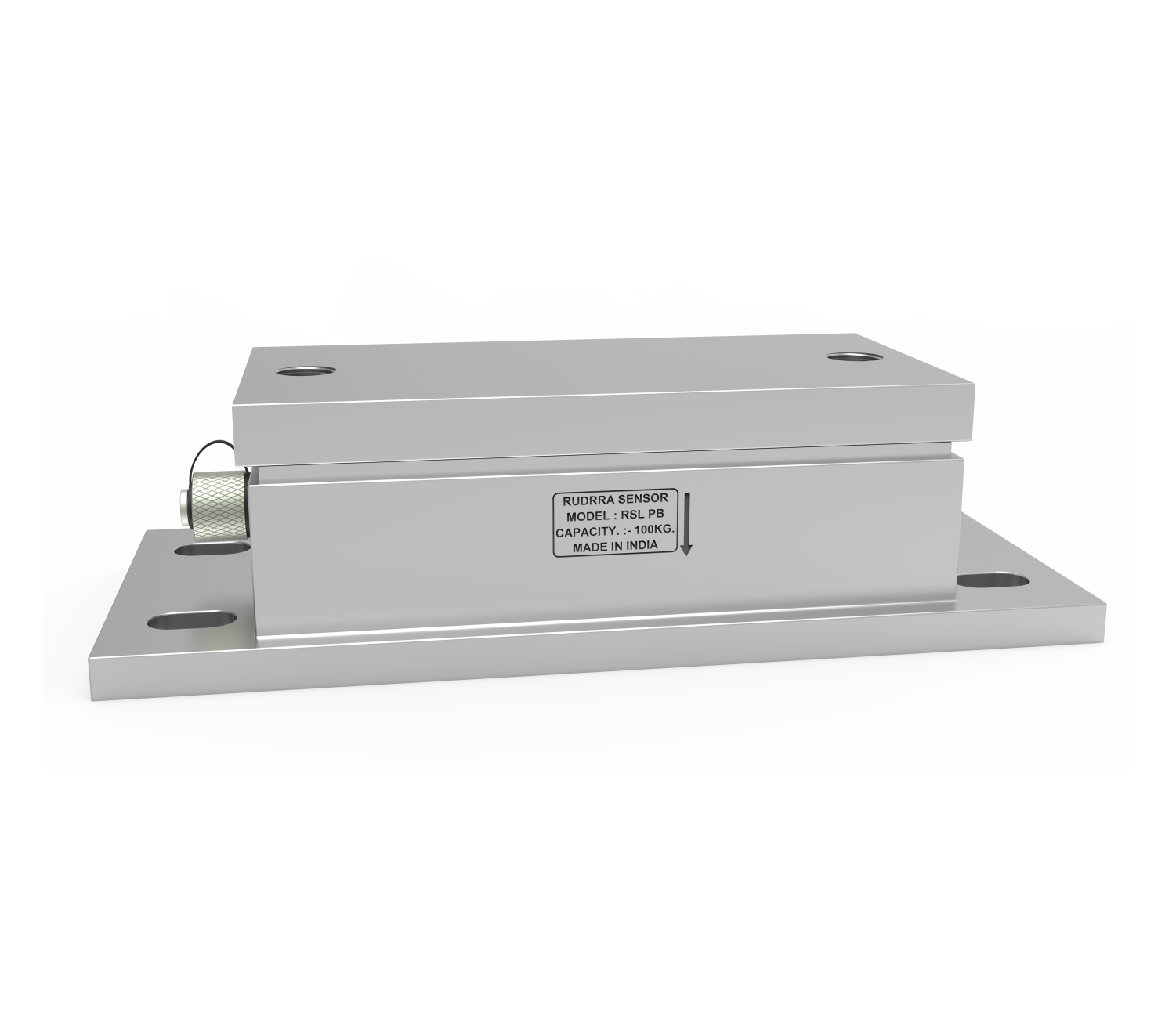

| Model | Web Tension Sensor – RS LP |

| Price | ₹12000 |

| Capacities | 25 kg, 50 kg, 100 kg, 150 kg, 300 kg, 500 kg, 750 kg, 1000 kg (1 ton), 1500 kg (1.5 ton) |

| Weight | 2.5kg, 6.5 kg, 11.50 kg, 14 kg |

| Delivery | 2 to 7 Working Days |

Key Features :

Large capacity range

High Strength Stainless steel construction

Special shielded cable and connector

Off-axis high strength to resist the force

Designed for web tension measuring

Easy mounting with clamp

High permissible operational speed for measuring roller due to high load cell spring coefficient.

Load Application Layout :

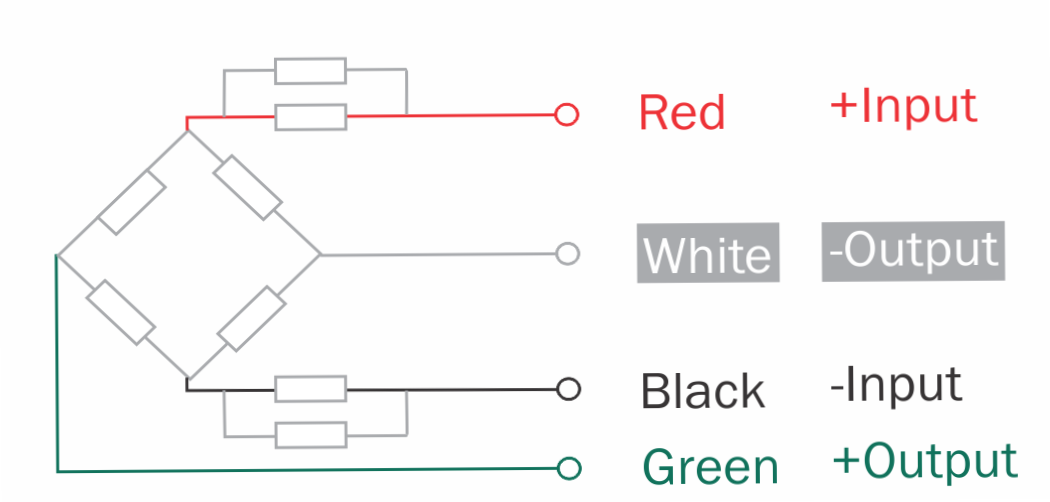

Cable Connection Details :

Dimensions :

CAPACITY (Kg) | L | L1 | L2 | D | D2 | D3 | D4 | D5 | D6 | Bearing |

25, 50, 100 | 40 | 3 | 34 | 107 | 17 | 23 | 40 | 60 | 6.5 | 1203 |

150 | 65 | 4 | 57 | 175 | 30 | 40 | 72 | 100 | 9 | 1306 |

300, 500 | 75 | 4 | 67 | 225 | 40 | 50 | 90 | 130 | 11 | 1308 |

1000 | 80 | 4 | 72 | 265 | 60 | 75 | 130 | 160 | 11 | 1312 |

Parameters : (Analog Load Cell)

Rated Load (kg) 25, 50, 100, 150, 300, 500, 1000 Kg

Download PDf File

Download PDf File